Extraction arms contribute to the ISO 14001 & 26000 policy

Mimault Tôlerie Industrielle is situated in Chapelle-Saint-Laurent, Deux-Sèvres in France. It is a family company, and it has been established in 1995. Originally it is a sheet metal factory. Its main processes still are the welding activities of thin metal sheets. Mimault employs about 25 people. Its ISO 14001 Environmental management standard and ISO 26000 Guidance on Social Responsibility approach makes it a professional company.

The challenge

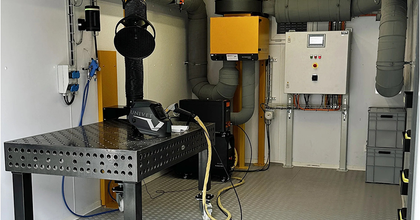

Metal fabrication is one of Mimault’s core businesses. This French company has a couple of welding workshops in its production facility. Most of the welders work with small metal workpieces. To use the floor space of the entire workshop optimally, all workplaces are relatively small as well. This means that many welders can work simultaneously on site.

One of the consequences was that all welding fumes accumulated into the workshop and generated a ‘blue layer’ inside the building, just below the roof. In order to remove this vast amount of welding fumes the employees opened all doors to create natural ventilation. Nevertheless, it was obvious that the open doors did not create enough general ventilation to remove all welding fumes. Mimault needed a professional extraction and filtration system to create a clean, safe and healthy working environment for its employees.

The solution

The challenge set by Mimault was crystal clear:

« The welding fumes inside the product facility needed to be removed as effectively as possible. »

Plymovent opted for a multiple arm system. A system solution that can cover many small workplaces. As the workbenches are fixed workplaces, the extraction arms could be installed easily, right above the workbenches. As Plymovent offers various extraction arms, each workplace was optimized. Three different types of extraction arms were installed. The KUA-3 (3 meters), KUA-4 (4 meters) and the FlexMax. The FlexMax can reach up to 5 meters.

Source extraction is always the most effective way to remove welding fumes. In the first place it protects the welder and secondly the welding fumes do not get a chance to linger and accumulate throughout the workshop. They are extracted into the extraction arms straight away, even before it reaches the breathing zone of the welder.

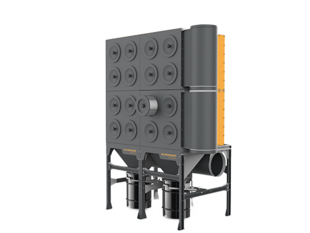

All extraction arms are installed to one central fan and filtration unit. The filtration unit requires little maintenance which is always a big advantage in a production environment where cleaning is already part of your daily working activities. Additionally, the silencer makes sure that the noise level stays within legal limits.

Main benefits

- All welding fumes are removed effectively, resulting in a healthy working environment.

- Maintenance-friendly system, the filtration unit makes sure that the filter cartridges are cleaned automatically by its RamAir technology.

- ISO 14001, thanks to the extraction and filtration system of Plymovent, Mimault strengthens her commitment towards the environment and its employees.

Testimonial

"We are a committed company to the ISO 14001 and are trying to get the ISO 26000 certificate. It gives us guidance. We feel that it is our responsibility to respect both the environment and our employees. Therefore, an unhealthy working environment could never be part of our policy."

"In the past we always opened the doors of the building to get rid of the vast amount of welding fumes. Still, we had a lot of welding fumes inside the building. Now, we can leave the doors closed and still have a clean working environment. Our employees notice the difference and are very satisfied with the extraction arms of Plymovent. They even feel better at work!"

Quote by: Mr Philippe Ménard, Managing Director at Mimault Tôlerie Industrielle

Product list

Products

"Now, we can leave the doors closed and still have a clean working environment!"

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all case studiesVentilation/filtration system main heat source

Effective removal of welding fumes & dust

The right extraction for a high-pressure aluminium die-casting machine

Complete extraction system ensures a safe working environment

Multiple arms improve work environment

MistEliminator units create a clean environment

Hessels is also going for the experience and expertise of Plymovent!

Effective welding fume extraction systems for all welding workplaces

Case New Holland is the first to choose Plymovent’s latest product: the MDB-Compact!

Welders appreciate and value effectiveness of Push-Pull system

U-Push-Pull system defeats welding fume clouds

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.