The right extraction for a high-pressure aluminium die-casting machine

Pedeo Hogedrukgieterij in Oudenaarde is a development partner and supplier of finished and assembled high-pressure die-cast zinc and aluminium alloy products. It boasts lengthy experience in the die-casting of high-pressure die-cast parts, allowing it to offer bespoke support during design.

The challenge

Pedeo uses high pressure to produce die-cast zinc and aluminium alloy products with the aid of a die-casting cell. Fumes and vapours are released at different points during the process, all of which need to be captured and removed. The correct solution is important in ensuring efficient temperature regulation is maintained in the production hall.

Pedeo’s newest high-pressure aluminium die-casting cell must be fitted with an extraction system to safely remove the fumes and vapours that are released. The fumes and vapours are released at different points throughout the process, such as in the furnace during aluminium smelting. In addition, fumes and vapours are also released during aluminium pouring and injection into the moulds, and when the moulds are opened and released. The challenge was in finding an extraction solution that could cover all of these different work stations.

The solution

The quantity of vapors, the speed at which they and the fumes rise due to heat development and the size of the new cell prompted Pedeo to opt for the Plymovent FlexHood as a solution.

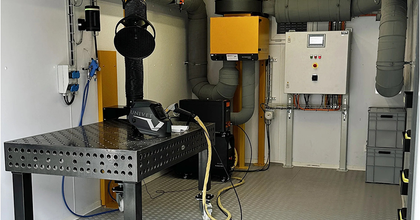

Plymovent installed several hoods, all connected to the new cell. One of the hoods is suspended over the furnace and equipped with fireproof slats that are suitable for use at high temperatures. The die-casting tube is also fitted with a customized extraction nozzle to extract the aluminium fumes at source. We also suspended two symmetrical hoods above the high-pressure die-casting cell to allow the handling equipment used to change the molds to pass over the machine.

The automatic start/stop function on the extraction system is connected to the high-pressure die-casting cell for energy efficient operation. The operator no longer needs to worry about operating the extraction system, as it switches on and off automatically.

The complete system was also fitted with a roof ventilator. To prevent the formation of moisture during the winter months, fresh air is drawn in from outside at the bottom of the extractor hoods to compensate for the loss of the warm air that is removed.

Main benefits

- Fully integrated with the high-pressure die-casting cell’s control system

- Minimal energy consumption

- Optimal use of the space above the machine

- Maximum extraction at source

- Bespoke solution

Testimonial

"The automatic start/stop function on the extraction system means that we can work as energy efficiently as possible. The operator no longer needs to worry about operating the extraction system, as it switches on and off automatically."

Quote by: Florian de Smijter, Process Engineer of PEDEO

Product list

Products

"We are very pleased with the compartmentalised approach to the problem. Plymovent’s bespoke solution means that we can now extract at source perfectly."

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all case studiesVentilation/filtration system main heat source

Multiple arms improve work environment

Case New Holland is the first to choose Plymovent’s latest product: the MDB-Compact!

Push-Pull system removes welding fumes effectively

Filtration of welding/grinding fumes and oil mist

Hessels is also going for the experience and expertise of Plymovent!

Complete extraction system ensures a safe working environment

U-Push-Pull system defeats welding fume clouds

Extraction arms contribute to the ISO 14001 & 26000 policy

Effective removal of welding fumes & dust

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.