Welders appreciate and value effectiveness of Push-Pull system

Potain is the Manitowoc brand of tower cranes. Potain was a French-based company founded in La Clayette, France, in 1928. The first crane was assembled in 1933. Manitowoc acquired the Potain brand in 2001. Manitowoc has three plants manufacturing Potain products in France. The main business at their Moulins site is fabricating steel components (jibs and cranes) for building tower type work site cranes.

The challenge

Mr. Guy Duret, Design Engineer of Manitowoc Cranes for Potain products, explains the challenge:

“Welding fumes are extremely fine and volatile and contain suspended metal particulates. We wanted to protect our operators from those particles. Some welding places were already provided by source extraction (extraction arms), but the size of the components we fabricate made it impossible to use only source extraction. Anyway, the multiple arm system was not fully satisfactory, as it did not offer complete protection for welders and non-welding personnel. They were still exposed to welding fumes. This is why we decided to use personal protective equipment. At the same time, we were also looking for a more complete solution to make the entire atmosphere in the workshops healthier.”

The solution

Considering the challenge, Manitowoc Cranes felt that a system involving the full recycling of the air was best suited to their requirements. Guy Duret continues:

“A representative of Air Liquide Welding’s* distributors Eutexia guided me towards the solution that we ultimately selected: a push-pull system. We paid a reference visit to a company in which a push-pull system of Plymovent was up and running and that convinced us of its effectiveness.”

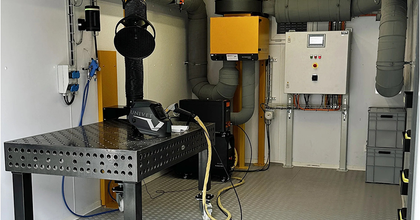

The push-pull systems consist of an outlet duct with grids at 5 m height at one side of the workshop and an inlet duct at the other side. A fan extracts the air through the inlet grids and brings it back through the outlet duct. This results in a horizontal flow of the air, which is in the meantime filtered by a self-cleaning filter system. As the welding fume is hot, it rises and is thus continuously captured by the duct system.

* Air Liquide Welding is an authorised distributor of Plymovent.

Main benefits

The push-pull system has appeared to be an effective and economic solution. The working conditions have been improved considerably and the same goes for the productivity. Also the welders are very pleased with the push-pull system:

“We noticed the difference at once - as soon as we stop welding, the workshop is clear and free of fumes. Previously, the fume cloud remained visible for a long time.”

“When you see the amount of dust in the containers, you realize what was going into our lungs in the past.”

Testimonial

“Safety is always first in our company culture. In that respect, the push-pull systems offer us a complete solution. You only have to see how clean the air is, even in a busy workshop. The quantity of particulate which is collected in the drums is additional evidence.”

Quote by: Mr. Guy Duret, Design Engineer of Manitowoc Cranes

Product list

"Safety is always first in our company culture. In that respect, the push-pull systems offer us a complete solution."

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all case studiesEffective removal of welding fumes & dust

Significant reduction of fume concentration

Multiple arms improve work environment

Push-Pull system removes welding fumes effectively

Effective welding fume extraction systems for all welding workplaces

Complete extraction system ensures a safe working environment

Case New Holland is the first to choose Plymovent’s latest product: the MDB-Compact!

The risk of fire under control with shield fire safety solutions

Filtration of welding/grinding fumes and oil mist

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.