Multiple arms improve work environment

G.C. Entreprise, Køge ApS was founded in 1984 in Denmark. Nowadays it has more than 20 years of experience with all kinds of activities in the construction industry. Today they employ 30+ people in no-dig solutions, cable laying and fibre optic installations.

The challenge

As a result of the annual review of the company’s work environment, it was decided to obtain a new extraction system. The service workshop needed a high-quality extraction system to remove welding fumes, grinding dust and oil mist, preventing accumulation in the workshop. The service workshop handles many different activities using an equally wide variety of machinery and tools. A flexible extraction solution was therefore a ‘must’. The main requirement was that the new extraction and filtration system should be able to handle: welding fumes, cutting fumes, grinding dust and oil mist.

The solution

Dansk Procesventilation ApS offered the following solution:

- Extraction from belt grinders with 2 x Ø 80 mm connections, directed to a cyclone via flexible hoses;

- Extraction for a pillar drilling machine via a MiniMan Ø 100 mm extraction arm;

- Extraction from a worktable via a KUA Ø 160 mm extraction arm.

To accomplish extraction from the worktable in the middle of the workshop plus various floor activities a FlexMax Ø 160 mm extraction arm was mounted with a reach of 5.5 m.

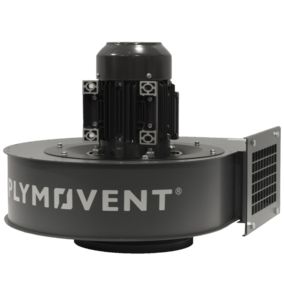

All extraction airflows are directed - via a centralised duct system - to the central filter MF-31 and FUA-4700 fan.

To switch the extraction system on or off the start/stop function is carried out with an on/off switch on all extraction arms, while for belt grinders the extraction starts automatically together with the belt grinder. The system is equipped with a mandatory control device.

Main benefits

- Welders and other personal are protected and will work in a healthier work environment from now on.

- Welding fumes, dust and mist do not accumulate throughout the workshop anymore.

- A flexible solution was implemented, easy to adjust to changing working conditions.

- Intelligent control device saves energy, thus costs.

Product list

Products

- FlexMax extraction arm 5.5 m Ø 160 mm

- KUA-2 extraction arm 2.0 m Ø 160 mm • MiniMan extraction arm 2.1 m Ø 100 mm

- Mechanical filter MF-31 with spark arrester

- FUA-4700 fan 2.2 kW

- Fan starter: SA-24

Applications

- Welding fumes

- Cutting fumes

- Grinding dust

- Oil mist

Find more information about the products here!

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all case studiesWelders appreciate and value effectiveness of Push-Pull system

The risk of fire under control with shield fire safety solutions

Effective welding fume extraction systems for all welding workplaces

Extraction arms contribute to the ISO 14001 & 26000 policy

Filtration of welding/grinding fumes and oil mist

Effective removal of welding fumes & dust

Ventilation/filtration system main heat source

The right extraction for a high-pressure aluminium die-casting machine

Hessels is also going for the experience and expertise of Plymovent!

Case New Holland is the first to choose Plymovent’s latest product: the MDB-Compact!

Push-Pull system removes welding fumes effectively

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.