Effective welding fume extraction systems for all welding workplaces

Baltimore Aircoil Company is one of the AMSTED Industries; each year approximately 3,000 units leave the BAC European manufacturing plant (Heist-op-den-Berg) which employ some 500 people. AMSTED Industries has the world’s most extensive line of factory-assembled and field-erected cooling towers, evaporative condensers, closed-circuit fluid coolers and thermal storage systems.

The challenge

The production activities of equipment such as cooling towers, condensers and cooling installations in aid of air conditioning systems require a lot of metalworking and welding. Baltimore Aircoil concluded for itself that the extraction of welding fumes and hazardous gases in the production halls could be improved. Therefore they decided to contact a specialist, to provide all welding workplaces in the production and assembling process with effective welding fume extraction systems. Thus guaranteeing the health and safety of its employees.

First an inventory was made of all existing welding fume extraction systems. Next, Plymovent came with an offer. This proposition was discussed in depth with the employees on the work floor. “Obviously, they make use of it day in day out and know what to look for”, says Straetmans, Production Engineer at Baltimore Aircoil. After this, every ‘t’ was crossed and every ‘i’ dotted, and Plymovent’s proposal was adjusted and approved.

The solution

Until recently, the welding fumes of the process of raw materials were extracted through source extraction. The previous arms were difficult to position. Moreover, the entire system was hard to maintain.

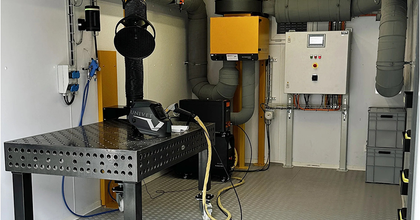

Plymovent has rearranged the workplace and provided it with a ‘fully controlled’ source extraction system including 10 UltraFlex extraction arms.

The control box and frequency controller ensure a constant extraction. Through an efficient fan and recirculation of valuable warm air the use of energy is minimized. Maintenance is kept to a minimum, thanks to the self-cleaning filtration unit. Another production line creates containers.

The previous extraction arms could not always cover the required space. A general filtration system offers more possibilities, which is why Plymovent installed a U-shaped push-pull system on that location. Welding fumes rise and are directly extracted through the pull grids into the ductwork. When using a general filtration system, welders need to be aware to use personal protection, such as an overpressure helmet.

Besides the systems mentioned above, Baltimore Aircoil also purchased a downdraft table, DraftMax. The DraftMax is a workbench and an extraction/filtration system in one, ideal for small assembly work.

Main benefits

- Enthusiastic employees; they actually see the difference compared to the previous welding fume extraction system.

- Practically maintenance-free; thanks to the self-cleaning filtration units SCS.

- Cost-efficient; thanks to recirculation of warm air.

- Excellent after-sales service of Plymovent.

Testimonial

“Of course, we already used welding fume extraction systems that indeed extracted part of the polluted air, yet not all of it. An additional problem was, that a major part of the warmth in the building was being extracted. So, we had to turn on the heaters. This is what we wanted to change.”

A year later: “The signals we receive from the work floor are positive. Our employees are very pleased that the welding fumes are now really being extracted and that they can perform their welding activities without problems. The self-cleaning filters are practically maintenance-free, making this solution much more economic.”

Quote by: Steven Straetmans, Production Engineer at Baltimore Alcoil.

Product list

Products

"Our employees are very pleased that the welding fumes are now really being extracted and that they can perform their welding activities without problems."

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all case studiesVentilation/filtration system main heat source

Complete extraction system ensures a safe working environment

Effective removal of welding fumes & dust

Case New Holland is the first to choose Plymovent’s latest product: the MDB-Compact!

Extraction arms contribute to the ISO 14001 & 26000 policy

Multiple arms improve work environment

Hessels is also going for the experience and expertise of Plymovent!

U-Push-Pull system defeats welding fume clouds

Filtration of welding/grinding fumes and oil mist

Push-Pull system removes welding fumes effectively

Welders appreciate and value effectiveness of Push-Pull system

MistEliminator units create a clean environment

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.