Case New Holland is the first to choose Plymovent’s latest product: the MDB-Compact!

Case New Holland and Plymovent have been working together successfully for 15 years already to combat welding fumes in the workshop of CNH. During these 15 years, many different systems of Plymovent have been installed in the factory in Zedelgem. The first system that Plymovent installed at CNH was the Push-Pull system in building number 20, where agricultural machines are produced. Air measurements were carried out after installation. These measurements demonstrated that the presence of welding fumes had reduced by 70 to 90%. Now, 15 years later, this system is still working optimally and to everyone’s satisfaction. In the meantime, a great number of other systems from Plymovent have been installed. CNH uses Plymovent's extraction arms, extraction hoods and Push-Pull systems.

The challenge

In one of the many production workshops in Zedelgem, there was a need for a new welding fume extraction system. It goes without saying that CNH contacted Plymovent. Thanks to the long-term cooperation between CNH and Plymovent, both companies are very aware of what they can do for one another and what they expect from one another. Welding takes place in the production workshop in question at various locations, spread across a large surface area. In addition, there is little space on the work floor for placing an extraction system located on the floor.

The solution

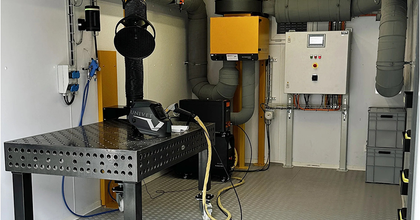

In order to use the space optimally, it was decided to install spatial extraction with a Push-Pull system, combined with Plymovent’s latest product, the MDB-COMPACT. The Push-Pull system was placed in a zone of 19 metres x 6 metres, to provide a flexible workspace to the welders. In view of the fact that it is a modular system, the workplace did not need to be completely modified. The specific work zones could be designated for new ventilation.

As there is little or no room on the floor of the workshop available for placement of the filter unit, it was decided to create a plateau on which the filter unit could be placed. The workbench could stay where it was, under this plateau. This plateau could not be too high, because sufficient space had to be left over above it for the travelling crane. The most suitable filter unit for this space was the latest product of Plymovent, the MDB-COMPACT. With its compact size, this filter unit is eminently suitable for placement in workshops where space is at a premium.

Main benefits

- Pre-assembled compact design with integrated fan

- Replacement of cartridges in front panel

- Easy to empty dust drawer

- SilentFlowTM duct free noise reduction for compact installation

- Ram-AirTM-pulse amplifier provides better cleaning for longer filter cartridge life and lower pressure loss

Product list

Time and time again Plymovent succeeds in offering the most innovative solution at a competitive price!

Apply for our newsletter

A breeze of fresh air in your mailbox?

Gallery

View other case studies

We have installed thousands of systems worldwide, for many happy customers. What to know who they are?

View all case studiesEffective removal of welding fumes & dust

Effective welding fume extraction systems for all welding workplaces

Extraction arms contribute to the ISO 14001 & 26000 policy

Ventilation/filtration system main heat source

Multiple arms improve work environment

U-Push-Pull system defeats welding fume clouds

Complete extraction system ensures a safe working environment

Hessels is also going for the experience and expertise of Plymovent!

Filtration of welding/grinding fumes and oil mist

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.