Air quality in the welding shop

The company RNO Kesselfabrik, located at Dettenhausen (Germany), is a manufacturer of highly efficient heating boilers for central heating systems. Wood pellets, being the fuel for these boilers, are CO2 -neutral and consequently contribute to an environmental-friendly way of heating.

Alfred T. Ritter, the principal shareholder, is likewise well known for his chocolate factory ‘Ritter Sport‘ and by his many and various environmentally relevant commitments.

The challenge

At the beginning, the welding fumes of the production facility were extracted by two fans. Soon this kind of extraction was not sufficient enough anymore, resulting in considerable fume and dust nuisance.

As the production expanded several welding robots and 11 manual welding workplaces were installed. It was then that the company management decided to purchase five welding fume extraction installations as central systems.

RNO processes about 16 tons of welding wire per year. The employees partly work in three shifts.

The solution

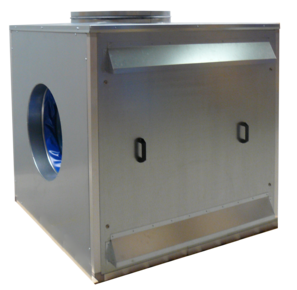

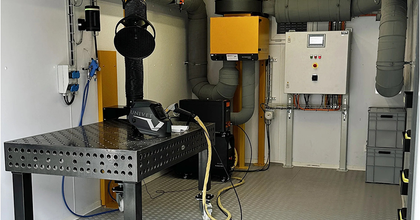

Five central systems consisting of filter systems type SCS with pre separator and fans type SIF-1500 (11 kW) were mounted. The welding fumes generated by the welding robots are captured by means of extraction hoods with baffles and side strips.

At the manual welding workplaces the welding fume is captured by extraction arms type UltraFlex-4/LC (length 4 m). These extraction arms were designed for low ceilings. Due to the mounted crane systems the application of traditional extraction arms was not possible.

A central duct connects the extraction points to the filter systems. To minimise the heating costs each installation is equipped with a summer/winter switch with air recycling duct (summer - exhaust to atmosphere, winter - recirculation).

Main benefits

- In order to guarantee the airflow the filter surfaces (150 m2) are cleaned by a automatic filter cleaning system during pauses, change of shifts and in the weekend. With this method compressed air shots are released in the interior of the filters which blow off the dust. The blown off dust falls into a dust container and is easy to remove. Due to the continuous cleaning a constant extraction capacity is guaranteed.

Testimonial

"Annual medical examinations have proved that the life quality of the employees has improved considerably due to the application of the welding fume extraction systems."

Quote by: Frank Zickermann, Assistant Head of Department at RNO Kesselfabrik

Product list

Products

"Our employees enjoy the improved air quality in the welding shop."

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all case studiesComplete extraction system ensures a safe working environment

The right extraction for a high-pressure aluminium die-casting machine

Extraction arms contribute to the ISO 14001 & 26000 policy

Push-Pull system removes welding fumes effectively

Effective removal of welding fumes & dust

Effective welding fume extraction systems for all welding workplaces

Significant reduction of fume concentration

MistEliminator units create a clean environment

Case New Holland is the first to choose Plymovent’s latest product: the MDB-Compact!

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.