Complete extraction system ensures a safe working environment

The challenge

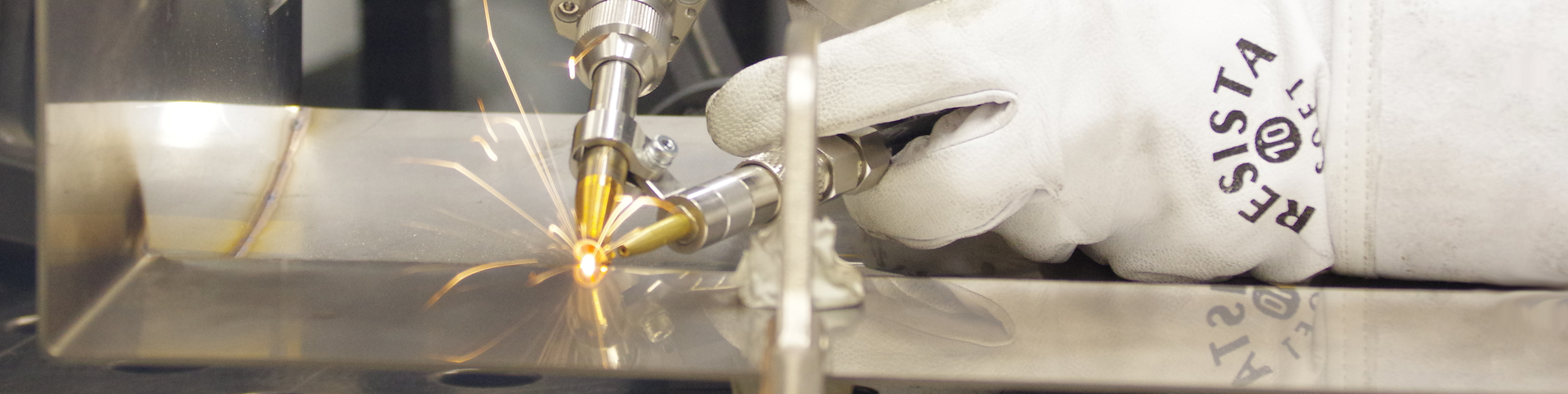

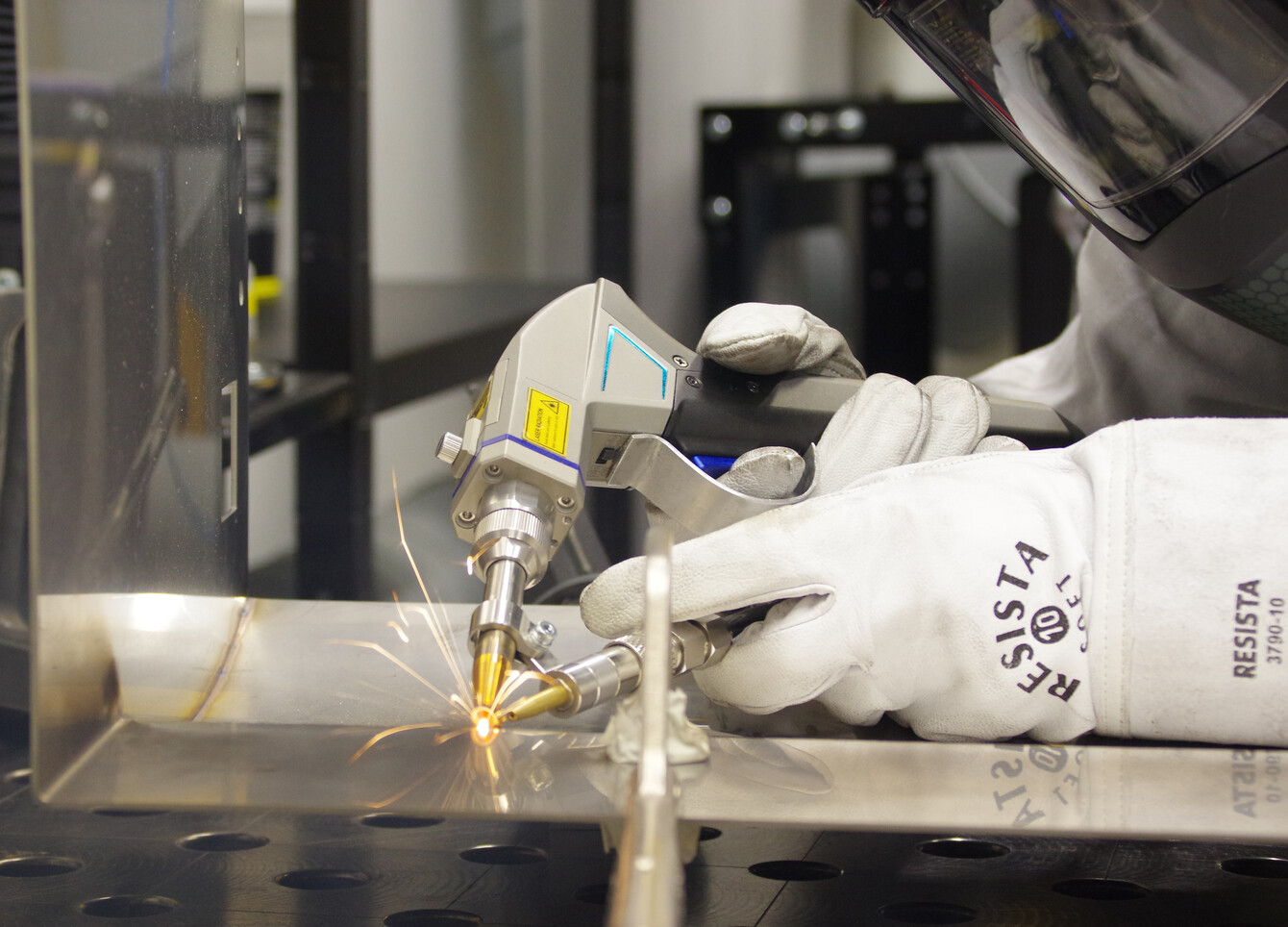

RuossTech AG faced the challenge of improving the efficiency and safety of the welding process. Handheld laser welding machines offered precision but also presented high safety risks. Thus, the team decided to develop a special welding container that provides complete protection from laser radiation, creating a safe work environment.

The container proved not only to be safer but also more efficient. Isolating the welding process improved workspace cleanliness and product quality. With increasing demand for welding services, RuossTech collaborated with Absaugtechnik Wild AG to install an advanced ventilation system that ensured optimal container performance.

This success led to new ideas: modular containers for further industrial applications. RuossTech’s innovations elevated their production processes and the entire industry.

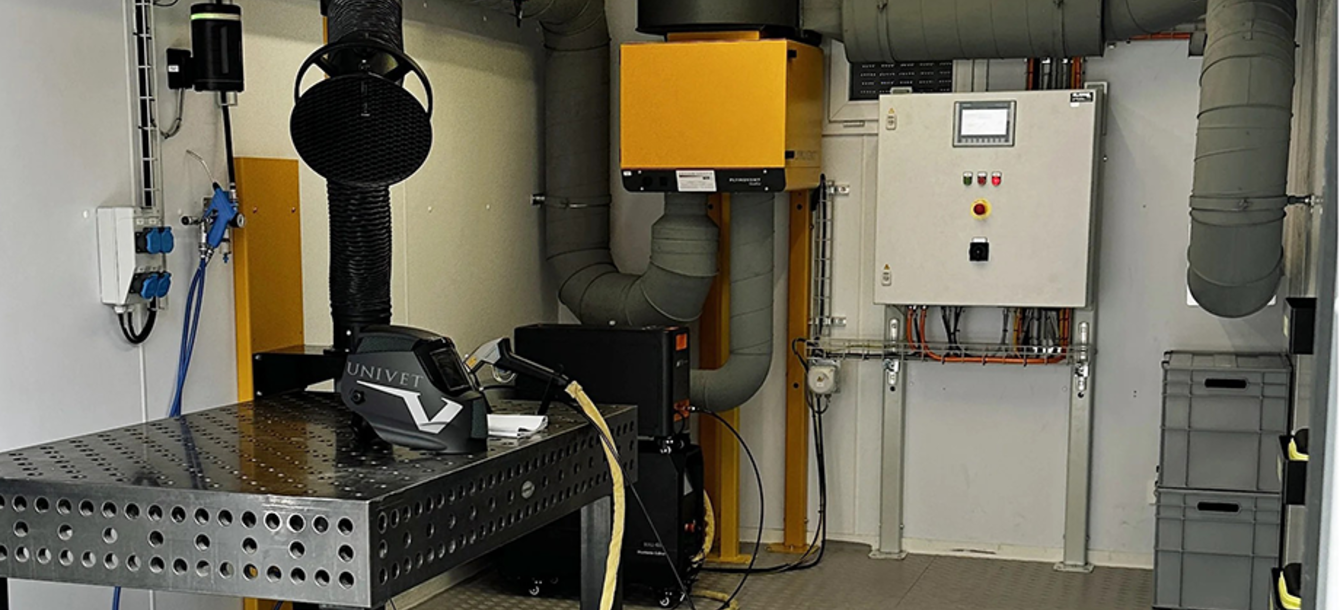

The complete extraction system provides a safe work environment.

The solution

RuossTech AG contacted the Swiss distributor for Plymovent, Absaugtechnik Wild AG, to inquire about installing an extraction system in the container.

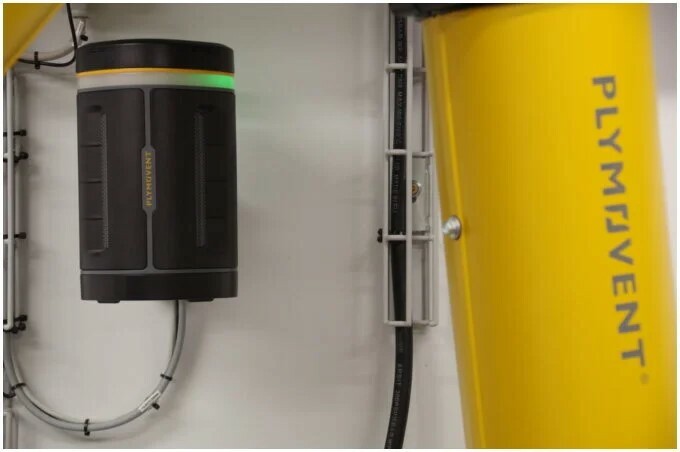

A standard garage container was procured, equipped with a Plymovent extraction device featuring Push-Pull, an extraction arm, and an AeroGuard air quality monitor. The complete safety control (SPS) was independently developed and implemented by RuossTech AG’s control engineering team. It includes control of the laser welding system (safety switch for

access to the work area) and automatic or manual control of the extraction system. This control system also monitors air quality and activates the Push-Pull system when necessary.

Additional safety components integrated into the system include a CO alarm and a TeleAlarm for lone work.

Product list

The company

RuossTech AG has been active in sheet metal processing, control engineering, and system construction for over 100 years, employing around 40 people at their site in Siebnen (SZ).

With a wide range of capabilities, from simple sheet metal parts to complex assemblies, including mechatronics and electrical control engineering, the company offers a broad portfolio.

Continuous modernization of processes and equipment, along with employee training, ensures a high-quality standard for the products manufactured.

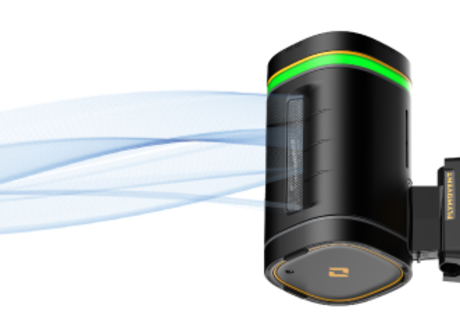

AeroGuard

AeroGuard helps you take control of the air quality in your indoor environment, creating a healthier and safer space.

Experience enhanced environmental awareness with our air quality monitor. The system provides real-time information on air quality through a free and userfriendly mobile app. Customize alerts for elevated pollutant levels to take timely action. AeroGuard can also activate external systems such as HVAC when needed.

Monitoring air quality ensures a safe and healthy indoor environment, helps prevent illnesses, and boosts productivity. If you have questions about AeroGuard as a key technology for clean and safe indoor air, please contact Plymovent or one of our distributors.

RuossTech AG and our Swiss distributor Abaugtechnik Wild AG have developed this solution using Plymovent products. Through this collaboration, clean air in the workplace is guaranteed.

Apply for our newsletter

A breeze of fresh air in your mailbox?

Gallery

View other case studies

We have installed thousands of systems worldwide, for many happy customers. Want to know who they are?

View all case studiesHessels is also going for the experience and expertise of Plymovent!

Extraction of exhaust gases in vocational colleges

MistEliminator removes oil mist effectively

Optimized filter system modification of the Audi RS5

Extraction arms contribute to the ISO 14001 & 26000 policy

Welders appreciate and value effectiveness of Push-Pull system

Significant reduction of fume concentration

Filtration of welding/grinding fumes and oil mist

U-Push-Pull system defeats welding fume clouds

Case New Holland is the first to choose Plymovent’s latest product: the MDB-Compact!

The right extraction for a high-pressure aluminium die-casting machine

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.