Extraction of exhaust gases in vocational colleges

The Lavoisier establishment comprises a vocational college and an apprentice training centre, which on 1 September 2018 became a UFA (apprentice training unit) of the Limousin academic training centre.

It offers courses leading to diplomas, certifications or qualifications. This training organization is a member of the GRETA du Limousin center and also offers courses for adults and employees.

The challenge

The Aquitaine Region’s project for Lavoisier college in Brive (19) involved bringing the exhaust extraction system for light vehicles up to standard at 33 workstations in around ten classrooms.

The aim was to find the ideal solution given the occupancy of the classrooms, and to comply with a regulatory rate of flow for light vehicles of 500 m³/h.

The solution

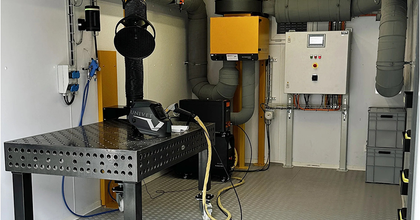

Taking into account the requirements of the teaching staff and the building layout, we divided the installation into 4 independent networks. This solution made it possible to adapt the system to the number of classrooms in use and to reduce energy loss from unused workstations.

The high position of each SER hose reel means it can be unwound close to the vehicle to be connected, and the installed EH-PV hose is crush-resistant. This solution prevents hoses from being left on the ground.

An REG nozzle with a collet has been fitted at the end of each hose to enable the system to adapt to most exhaust pipes.

Each installation is controlled by a variable frequency drive (VFD) to achieve a precise flow rate of 500 m³/h per station. Suction is started by an MSR switch on each SER hose reel, which detects when the hose is unwound.

The system also shuts down automatically. When all the hoses are stored on the SER reels, the SIF fan stops.

Main benefits

- Extraction for 33 workstations can be provided simultaneously

- EH-PV crush-resistant hose and versatile REG connection nozzle

- Precise rate of flow with fan controlled by a variable frequency drive

- Minimisation of energy losses

- Fewer suction hoses on the floor (reduced risk of students falling)

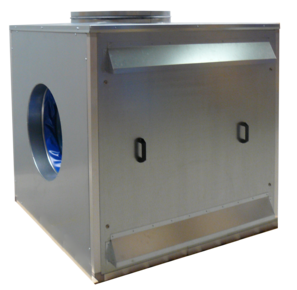

- Fans located outside in soundproof boxes to reduce the noise impact in the workshop

Testimonial

“The work carried out and the equipment installed have improved training and working conditions, as well as upgrading the extraction network.

The previous network was totally obsolete and did not work, so there was no extraction in the workshop, posing a health risk to students and teachers. The new network has completely cleaned up the air in the workshops by providing an efficient extraction system and by refreshing the workshop air through vents not connected to the vehicles at any given time. In addition, this work has enabled us to set up the extraction system layout in line with current teaching requirements. We were able to create 4 separate extraction zones and distribute the nozzles differently.

We’re very pleased with the result and would like to thank the Nouvelle-Aquitaine region for funding the work.”

Quote by: Mr Jérôme Rodrigo, Deputy Director of Vocational and Technological Training at the Lavoisier College and apprentice training unit in Brive (19)

Product list

Products

"The new network has completely cleaned up the air in the workshops by providing an efficient extraction system and also by refreshing the workshop air through vents not connected to the vehicles at any given time."

Questions after reading the article?

We're happy to help!

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all case studiesExtraction hood XL removes welding fumes in training facility

Plymovent sponsors The Welding Academy

Clean and fume free environment for students

MistEliminator removes oil mist effectively

Technical school satisfied with effective downdraft & backdraft workbenches

Optimized filter system modification of the Audi RS5

Complete extraction system ensures a safe working environment

Production lines with plenty of room in newbuild production hall

Exhaust extraction for Mazda workshop in Paramatta Australia

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.