Optimized filter system modification of the Audi RS5

ThyssenKrupp System Engineering is an international subsidiary of ThyssenKrupp Solutions AG, a systems partner for all key components in the body work and driveline process chain. ThyssenKrupp offers series production for a number of very sophisticated systems and components in the automotive sector, including, in particular, body construction. The company processes conventional materials as well as lightweight products, including during series ramp-up and ramp-down and when customers require spare parts. ThyssenKrupp’s particular strength lies in the construction of overall bodies or subassemblies in aluminum and mixed construction — manually, partly automated or fully automated.

Spaceframe components are manufactured to paintable bodies in manual and automation processes. As such, ThyssenKrupp System Engineering is able to cover all stages of manufacture from the prototype through to series and spare parts production. Lamborghini Gallardo and Aventador, McLaren and Audi RS5 Cabrio are just a few examples of the brands for which ThyssenKrupp System Engineering has completed bodywork.

The challenge

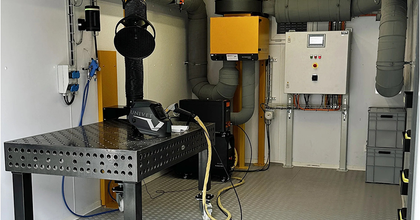

The Audi A5 is prefabricated as a special design Cabrio RS5 at ThyssenKrupp in Heilbronn. The preparatory work involves drilling holes in the body floor of the chassis, while the machining step involves both plasma cutting and plasma welding. The fumes produced by these processes, in addition to accruing, glowing metal particles, cannot be extracted from above.

The solution

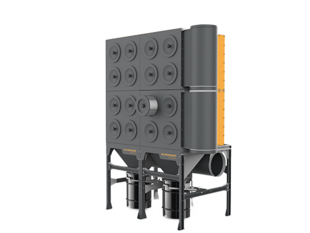

Plymovent was able to devise a bespoke solution for the company. The system was installed in such a way that it was also able to integrate elimination of flying sparks from below, ensuring simultaneous extraction of rising vapours and fumes on the one hand, and descending particles on the other. A complete FireShield program was chosen for the installation, which incorporates the capture of fumes and preventive fire suppression thanks to an OilShield and Sparkshield. The program is complemented by a SparkDetector and SmokeDetector, equipped with a temperature sensor. This system not only minimizes the risk of filter fires but also the consequential damage associated with the outbreak of fire in a filter system.

Main benefits

- The system has succeeded in not only extracting rising vapors but also in extracting glowing, descending metal particles.

- Clean air throughout the production hall.

- Maximum safety against fires through prevention, alerts and fire suppression.

Testimonial

"The bespoke solution has allowed us to extract both the rising fumes and the particles. The combination of Plymovent Sparkshield with Plymovent OilShield gives us reliable protection against fires in our plant. These protection measures are complemented by a FlameShield, a fire extinguishing generator. Every one of our requirements is fulfilled to the max."

Quote by: Mr. Mattias Martin, Head of Maintenance at ThyssenKrupp

Product list

Products

"The bespoke solution has allowed us to extract both the rising fumes and the particles."

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all case studiesMistEliminator removes oil mist effectively

Extraction of exhaust gases in vocational colleges

Production lines with plenty of room in newbuild production hall

Exhaust extraction for Mazda workshop in Paramatta Australia

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.