Health protection of the employees

The company was founded in 1973 by the young Karlheinz Wiesheu, an enterprising young butcher whose first sales success was selling ovens to butcher shops. Nowadays WIESHEU sells between 6,000 and 6,500 baking ovens per year. Mainly to bakeries and the food retail market. However, also butcheries and filling stations with convenience store have come to appreciate the reliable ovens of WIESHEU.

Despite a sluggish domestic economy, in 2007 WIESHEU turned over in excess of € 59, 5 million, up 11% on the previous year, and employs around 350 people. Strong partnerships and links within the EU, for instance with the French oven maker Fringand, as well as with former socialist countries and Asia, are stimulating strong growth in the international market.

The challenge

WIESHEU GmbH, situated in Affalterbach (Germany), is one of the leading European manufacturers of innovative and stylish ovens for baking. They manufacture products of stainless steel. Processing stainless steel requires special instructions to regulate the health protection of your employees.

Therefore, those responsible within the company have decided to equip the welding workplaces with source extraction.

At source extraction remains the most effective extraction system for capturing welding fumes, by far. Plymovent offers various fixed and mobile solutions for at source extraction. Extraction arms, mobile and stationary units are extremely user-friendly, easy to install and use. By fitting individual fans to each arm, like WIESHEU did, optimum extraction is guaranteed!

The solution

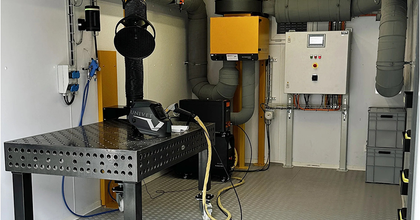

The welding area has a low ceiling. As a consequence, traditional extraction arms could not be used. Fortunately, Plymovent has extraction arms in their portfolio that are especially designed for low ceilings. Four extraction arms type UltraFlex-4/LC (4 m) were mounted. Each extraction arm is connected to a separate fan and stationary unit type SFS.

The arms work with an automatic start/stop device in combination with a welding cable sensor.

When the welder begins, the extraction device starts; when the welder is finished, the device shuts down. Thus it is guaranteed that the polluted air is only extracted during welding activities. On top of that the installation works according to the emission guidelines for alloyed materials.

Main benefits

- Extraction arms are easy to operate

- The BalanceWheel® system keeps maintenance to a minimum

- Energy saving, thanks to welding cable sensor

- Very effective extraction of welding fumes

- Clean, safe and healthy work environment

- Less sickness notices

- The stationary unit type SFS are automatically cleaned by compressed air, that guarantees a long-lasting filter lifetime

Testimonial

“I’m very glad we made this investment. Thanks to purchasing four extraction systems of Plymovent the breathing zones of the employees remain pollution-free. This certainly has a positive effect on the sick leave. I’m glad the fume is gone since we have this installation."

Quote by: Tobias Kuhn, Welder at WIESHEU GmbH

I’m very glad we made this investment. This certainly has a positive effect on the sick leave.

Gallery

View other case studies

We have installed thousands of systems worldwide, for many happy customers. What to know who they are?

View all case studiesSignificant reduction of fume concentration

Welders appreciate and value effectiveness of Push-Pull system

The risk of fire under control with shield fire safety solutions

Complete extraction system ensures a safe working environment

Ventilation/filtration system main heat source

Case New Holland is the first to choose Plymovent’s latest product: the MDB-Compact!

Filtration of welding/grinding fumes and oil mist

MistEliminator units create a clean environment

Effective removal of welding fumes & dust

U-Push-Pull system defeats welding fume clouds

Multiple arms improve work environment

Push-Pull system removes welding fumes effectively

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.