MistEliminator removes oil mist effectively

Bulten is one of the largest suppliers of fasteners to the European automotive market. They develop, produce and market a wide range of metallic fasteners and related services. Bulten’s offer also includes technical development, materials, production know-how and logistics as well as Full Supplier Provider concepts. The head office is based in Gothenburg, Sweden and this manufacturing unit is based in Hallstahammar, Sweden.

The challenge

Bulten, situated in Sweden is a manufacturing facility. They use cold forming machines to manufacture fasteners, like screws, bolts, valves, etc. Bulten uses metalworking fluids to cool down the products themselves, and to ensure that the machinery and tools do not get rusty. During this metalworking process oil mist arises. These cold forming processes take place in closed and half open dedicated machine centres. Effective capturing, filtration and removal of oil mist is a must to protect the staff’s health, create a safe work environment and extend the lifespan of Bulten’s machinery and tools.

Bulten was already using filtration units. Each machine centre used to have its own filtration unit. However, those needed to be replaced by a new system solution to support five cold forming machines altogether.

The solution

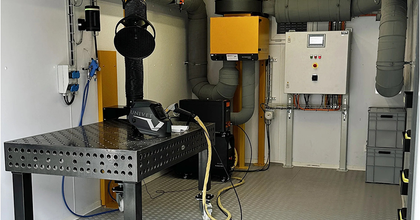

One of the main challenges was to get all capturing, filtration and removal of oil mist centralised. Thanks to the ‘single and dual base filter bank’ possibility this was a done deal for Plymovent. The ME-42/2 single base filter banks are installed in two rows.

The PLC unit makes it possible to have all filtration units automatically controlled. This makes the MistEliminator very user-friendly. The filter cassettes of each filtration unit are being drained on a daily basis, according to Bulten’s needs.

The ME-42 is fitted with an additional HEPA filter. The HEPA filter ensure recirculation. Recirculation ensures that expensively heated air stays within the workplace. Not only does this save energy, it also reduces Bulten’s heating and ventilation costs.

The automatic pump, OilPump (this is an option), moves the re-claimed oil from the container beneath the filter banks to a tank without operator intervention.

Fact

Total airflow (when all machines are running) is 26,000 m3 /h and the filter capacity is 32,000 m3 /h.

Main benefits

- The self-draining filter cassettes ensure effective filtration of oil mist.

- The PLC, controlling the draining process, makes the unit even more maintenance-friendly.

- Clear sight within the closed and half open cold forming machines.

- Energy saving, thanks to recirculation.

Testimonial

“We are very pleased with the ME-42 filtration units of Plymovent. The fact that they are available as single and dual base filter banks is perfect! This way, we created one SUPER filtration unit of eight ME-42/2 units, all connected to one fan.”

“Each filter unit has an automatic damper, 16 pieces in total. These are controlled by a central PLC box that shuts down the airflow in each filter unit for 1.5 hours to drain the filter cassette. This time can, of course, be adjusted to our needs. The plant is running 24 hours a day, so the draining of filter cassettes takes place continuously.”

Quote by: Ralf Björklund, Production Manager at Bulten in Hallstahammar

Product list

Installed system:

- MistEliminator filter units, 8 x ME-42/2

- PLC

- 16 x automatic damper Ø 250 mm

- FAN 37 kW

- DCV controller

- TG-2500 pressure transmitter

- OilPump, automatic pump

Find more information about the MistEliminator here!

"We are very pleased with the ME-42 filtration units of Plymovent. The fact that they are available as single and dual base filter banks is perfect!"

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all casesComplete extraction system ensures a safe working environment

Fully controlled multiple arm system removes welding fumes effectively

Effective extraction systems in testing area

Optimal employee protection against welding fume

Minimum environmental impact, maximum air purity

Global preferred supplier with eds solutions

Clean working environment without oil vapours

Saving valuable energy during the heating season

Extraction of exhaust gases in vocational colleges

Production lines with plenty of room in newbuild production hall

Exhaust extraction for Mazda workshop in Paramatta Australia

Push-pull systems in the transport industry

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.