Case studies

"Our downdraft table, the DraftMax Advance of Plymovent, is by far the best I’ve ever seen."

Welding fume capture and filtration at Aceromas

ACEROMAS upgraded its welding area with a flexible source-extraction solution installed by our Chilean distributor Ambitec. The new setup captures fumes right where they’re generated and keeps the workspace clean and comfortable. Welders immediately noticed better visibility and no lingering welding smell.

Tailored Fume Extraction Installation in Quebec

Modern Event Furniture, previously outsourcing their welding operations to China, decided to bring welding in-house at their new facility in St-Laurent, Quebec, to reduce costs. To maintain safe working conditions, they required effective fume extraction for their welding area without installing a large, costly system. Go 2 Industrial installed 2 WallPro Double wall-mounted fume extractors.

Exhaust extraction for Mazda workshop in Paramatta Australia

The Mazda workshop in Paramatta has installed a modern exhaust extraction system to meet the highest safety and environmental standards. The solution ensures efficient exhaust gas extraction, improves working comfort and optimizes energy efficiency.

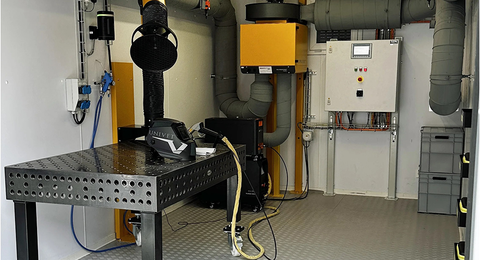

Complete extraction system ensures a safe working environment

Isolating the welding process improved workspace cleanliness and product quality. With increasing demand for welding services, RuossTech collaborated with Absaugtechnik Wild AG to install an advanced ventilation system that ensured optimal container performance.

Extraction of exhaust gases in vocational colleges

The project for Lavoisier college in Brive involved bringing the exhaust extraction system for light vehicles up to standard at 33 workstations in around ten classrooms.

Case New Holland is the first to choose Plymovent’s latest product: the MDB-Compact!

In one of the many production workshops in Zedelgem, there was a need for a new welding fume extraction system. It goes without saying that CNH contacted Plymovent.

Effective removal of welding fumes & dust

The welding activities at Scania generate a lot of welding fumes. Plymovent installed a multiple arm system, extraction hoods, central filter system.

Safety of the welder ranks first

FIMA required a modern, user-friendly system which was regarded as the most important demand for their 14 new welding workplaces. The extraction system of Plymovent was selected.

Air quality in the welding shop

At the beginning, the welding fumes of the production facility were extracted by two fans. Soon this kind of extraction was not sufficient enough anymore, resulting in considerable fume and dust nuisance.

Effective extraction systems in testing area

The welding fumes of the two welding robots are captured by extraction hoods and filtered by two self-cleaning cartridge filters type SFS.