Control of oil mists to purify workshop air

Founded in 1967, CAZENAVE has evolved continually in order to be able to fulfil the requirements of its customers. It has become a leading partner to the major aerospace companies thanks to its know-how in the field of surfacing, turning, cutting and assembly of high-precision parts. Currently it employs 79 people at its works in Serres Castet (Pyrénées-Atlantiques, France).

The challenge

The company CAZENAVE has 23 CNC machine tools in its workshop. With the aim of purifying its workspace environment while simultaneously preventing energy wastage (because any air discharged to the outside must be replaced by an equivalent volume of air), it appointed Plymovent to conduct a filtered air recirculation project involving the installation of an air mist extraction system, which at the same time provides industrial flexibility to fulfil future requirements such as changes in the position of, or replacement of the CNC machines.

The solution

To meet the customer’s needs, Plymovent has installed 14 oil mist removal filters, to which it has added the options necessary to ensure flexible use:

- A trolley for displacing the filters (to facilitate their maintenance or change their locations in the workshop)

- A variable frequency drive in the control box (to adjust the extraction flows)

- A box containing a washable pre-filter (to prevent discharges of oil and metal chips, and thus increase the lifetime of the filters)

- A visual indicator (to check their condition)

Main benefits

- Employee health is protected because oil is no longer released into the atmosphere;

- The system delivers energy savings thanks to its air recirculation;

- Filter service life is extended due to the installation of a pre-filtering box at each numerical control.

Testimonial

“The results are there: there are no more oil mists suspended in the workshop with a filtration rate of 99.5 %. This system that eliminates everything is probably the first of its kind in France. “

Quote by: Mr. Stéphane BLANC, Logistic Manager at Cazenave

Product list

"This system that eliminates everything is probably the first of its kind in France."

Gallery

View other cases

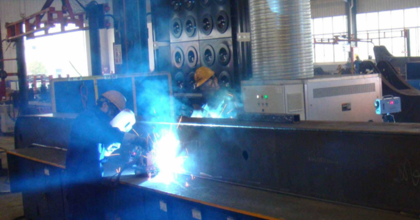

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all casesEffective extraction systems in testing area

Clean working environment without oil vapours

Fully controlled multiple arm system removes welding fumes effectively

Global preferred supplier with eds solutions

Optimal employee protection against welding fume

MistEliminator removes oil mist effectively

Push-pull systems in the transport industry

Saving valuable energy during the heating season

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.