Minimum environmental impact, maximum air purity

NEUERO was founded in 1914 as a manufacturer of agricultural machinery. In the years after World War II, the production range was expanded to include mobile pneumatic conveyor systems, which were used worldwide in the unloading of seagoing and inland waterway vessels. The production of turbo radial fans was also started especially for the pneumatic conveying of bulk material. In 1988 the NEUERO-Group was broken down three independent companies. Since then NEUERO Industrietechnik is a specialist for pneumatic ship unloading and mechanical ship loading worldwide.

NEUERO follows the “Made in Germany” tradition with over one hundred years of activity in the production of reliable and high-quality conveyor-systems.

At the Melle site there is a 69965 ft2 (6500 m²) production area with a new logistics hall. Equipped with their own production machine, a paint shop, a sandblasting cabin and its own test laboratory, the company is able to implement continuously the newest finding of engineering solutions.

The challenge

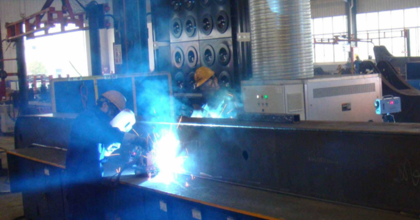

NEUERO had old extraction systems in use. A filtration of the hall air did not take place at this time, since the welding smoke was emitted by fans to the outside over the roof. None of the fans were operational at the time of the inspection. In discussion with the management, three alternatives for the 17 extraction points were argued, 60% of them are operating simultaneously.

- Single place extraction via the roof

- Recirculation mode, decentralised with summer/winter switching

- Central system with summer/winter switching

The solution

Due to the efforts to pollute the environment as little as possible, while at the same time complying with all limit values to protect the health of employees, this possibility is (first possibility) categorically excluded by the management. The possibility of decentralized extraction (second possibility) is also not acceptable due to the immense space requirements.

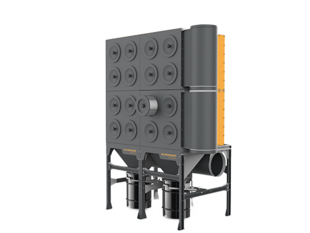

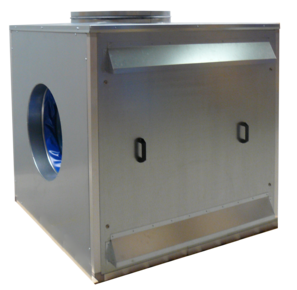

The company NEUERO Industrietechnik opts for the central extraction system, which is the most space-saving and effective way of air filtration. For the collection and filtration of the particles resulting from welding, a central extraction system, supported by collection devices directly at the source of origin, is planned.

Main benefits

- No “wasted” hall space

- Optimum hall air, compliance with limit values

- Precise fitting extraction at the source

Testimonial

“Our air quality is significant optimized through filtration and heat recovery. The extraction performance has improved considerably compared to the old version."

Quote by: Helmut Stolle, Head of Facility Management at NEUERO

Product list

Products

"The extraction performance has improved considerably compared to the old version."

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all casesMistEliminator removes oil mist effectively

Global preferred supplier with eds solutions

Push-pull systems in the transport industry

Clean working environment without oil vapours

Optimal employee protection against welding fume

Fully controlled multiple arm system removes welding fumes effectively

Effective extraction systems in testing area

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.