Push-pull systems in the transport industry

Zoomlion Heavy Industry Science & Technology Development Co., Ltd. is a Chinese company, founded in 1992. It has subsidiaries, marketing and research institutions, a complete sales network and manufacturing bases located all around the world, employing over 4,000 people. Its annual turnover is more than 5,6 billion RMB (€ 682,180,800).

The challenge

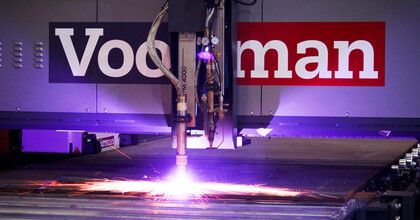

Zoomlion, based in China, produces all kinds of enormous vehicles/machines, e.g. to asphalt, pave, drill, sweep and wash, but also crane transportation, bulldozers and fire trucks; all heavy machinery. One of its subsidiaries, based in Changsha1 , was looking for a solution to remove the overdose of welding fumes from its workshop. This subsidiary is huge: 95,000 m2 (207 m x 72 m x 14.6 m) and includes three bays.

The welding area covers 180 m x 72 m x 5 m; 180 employees work in two shifts, seven days a week. Besides manual welding, welding installations are used. All together consuming 60,000 kg of welding wire per month. Plymovent analysed the situation carefully and proposed an engineered solution.

1 Changsha is the birthplace of China’s mechanical engineering technology.

The solution

Plymovent has taken the following things into account creating an engineered solution for Zoomlion:

- Heavy development of welding fumes and grinding dust.

- Large workplaces (due to the large workpieces): source extraction is not an option.

- Intensive welding, constantly 24/7.

- No existing roof (or other) ventilation systems.

- High personnel costs per welder, due to annual medical inspections.

First, Plymovent inspected the manufacturing site. They drew a professional system design, started with test settings and made a quotation for the entire project.

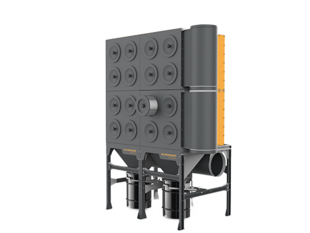

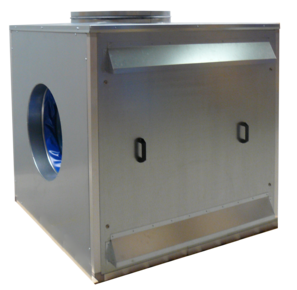

Plymovent advised a general filtration system; in this case four parallel Push-Pull systems. Push-Pull systems are a perfect solution if welders work with large workpieces.

Welding fume rises due to its heat. Ductwork is being placed at exactly that height, where the welding fumes remain floating. Push grids in the ductwork push (airflow) the welding fumes to the other side, where as pull grids in the opposite ductwork attract the welding fumes. The welding fumes are transported to the central filter system, which then cleans the polluted welding fumes and dust. The filtered clean air is brought back into the workshop (recirculation).

Main benefits

- Safer working environment, better view (less dust and fumes), cleaner work floor.

- Healthier working environment, less medical costs.

- Less absence due to illness, higher productivity.

Testimonial

“We are very happy with the engineered solution provided by Plymovent. As a professional company, Plymovent analysed our manufacturing facility first and came up with a well-considered system design. They ran a test in zone 3 and eventually installed four Push-Pull systems. Everybody notices the big difference, less fumes and dust; thus a safer and healthier workplace!”

Quote by: Mr. Chen, Sr. Technical Manager at Zoomlion

Product list

Products

"The Push-Pull systems of Plymovent ensure a clean environment."

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all casesMinimum environmental impact, maximum air purity

Clean working environment without oil vapours

Global preferred supplier with eds solutions

Effective extraction systems in testing area

MistEliminator removes oil mist effectively

Fully controlled multiple arm system removes welding fumes effectively

Optimal employee protection against welding fume

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.