Effective extraction systems in testing area

As a pioneer in the field of brake testing technology, MAHA has specialised in the testing of safety-relevant components and driving properties of all types of vehicles for almost four decades. MAHA has been active in vehicle lifting technology with great success for over 25 years.

The challenge

With a team of over 1,000 employees, the engineers and technicians at MAHA provide answers and solutions for all questions involving vehicle safety testing and lifting technology. Their clients include vehicle manufacturers, test organisations, governments and workshops. Their extensive sales network guarantees an efficient worldwide service readiness and timely spare part supply.

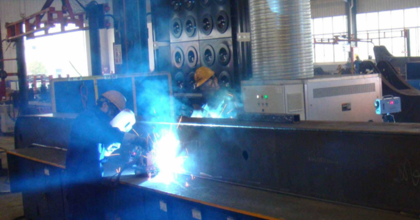

The welding activities are spread over the whole production area. MAHA processes about 60-65 tons of welding wire per year.

The solution

Situation-related the management has decided to apply several solutions:

- The fixed workplaces were equipped with stationary filters type SFD with a filter surface of 50 m2 and extraction arms with NEC extension cranes (4 + 2 m) with a reach of 6 m.

- The welding fumes of the two welding robots are captured by extraction hoods and filtered by two self-cleaning cartridge filters type SFS.

- For the flexible workplaces mobile fume extractors type MFD with extraction arms 4 m or stationary filters type SFS with extraction arms 4 m have been selected. Also our small, mobile high vacuum systems type PHV are applied.

Main benefits

- The mobile and stationary filters (MFD respectively SFD) have a very long lifetime due to the large filter surface of 50 m2.

- The filter cartridges of the stationary SFS filters which are connected to the extraction hoods are equipped with an automatic filter cleaning system. With this system the filter cartridges are cleaned from the inside by means of compressed air, thus guaranteeing a very long durability of the filters.

- The responsible workers and also the staff describe the applied systems as solid, reliable and powerful.

Testimonial

“With the different types of extraction every welding workplace is equipped with its own effective extraction system. With these high performance installations, we hardly can make any money out of spare filters!"

Quote by: Marcus Sutter, Supplier

Product list

Products

"With these high performance installations, we hardly can make any money out of spare filters!"

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all casesFully controlled multiple arm system removes welding fumes effectively

Push-pull systems in the transport industry

MistEliminator removes oil mist effectively

Minimum environmental impact, maximum air purity

Optimal employee protection against welding fume

Saving valuable energy during the heating season

Global preferred supplier with eds solutions

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.