Push-pull systems for protection of employees

Since 1922, ACV has been designing, manufacturing and distributing systems and solutions for hot water heating and commercial and domestic heating installations. All the products, which are manufactured in stainless steel, (water heaters and boilers) and certain ranges of heat-only or regular boilers are essentially manufactured on the main site of 35,000 square metres in Seneffe, Belgium. Similarly, engineering, training and product export services are also located on the Seneffe site.

The challenge

Production activities require a significant amount of mechanical/ welding work. ACV is recognised for taking precautions and implementing the measures necessary to protect its employees against harmful welding fumes during production. As part of a large modernisation and optimisation project that has been taking place since 2016, a large workshop was built.

ACV wanted a welding fume extraction system for this new workshop which would ensure that the concentration of fumes would be less than 1 mg/m³. Consequently, they decided to bring in a specialist who would be able to provide a solution to fulfil the requirement. After carrying out a study of the production process and the various welding stations, Plymovent proposed an appropriate solution. Each point was investigated in detail and the offer proposed by Plymovent was validated.

The solution

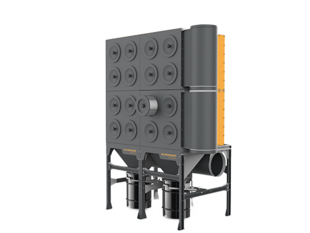

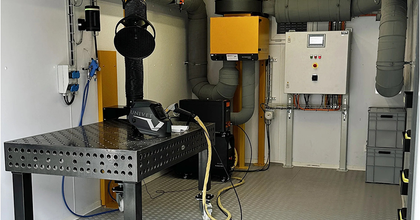

Because of the large size of the parts and frequent position changes, extraction at source was not the ideal choice. Consequently, a general filtering system was selected. In this case, the workshop (40x40m) was equipped with a U-shaped Push-Pull system, comprising an MDB-40 stationary filter and a 45 kW fan. Due to the large size of the workshop, the system was divided into two sections of 20 x 40 m to optimize the air flow. The Push-Pull system was installed at a height of about 5 meters.

The welding fumes are captured by the Push-Pull flow of air and discharged into the system inlet grilles. After filtering, the clean air is recirculated into the workshop by push ducts (thrust grilles). This constant flow ensures continuous elimination of welding fumes and other particulates.

Main benefits

- Healthy working environment

- Elective maintenance thanks to the self-cleaning MDB filtering units

- Cost-effective, due to air recirculation that optimises energy use

- Excellent after-sales service, single point of sale

Product list

Products

"Plymovent was the last supplier consulted but the first to come up with a solution. The preparations and work carried out by the team were faultless."

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all cases