Operator, once again, happy to work on machine

Mervers NV was founded in 1945. Since the 1970s has been chiefly active in the chemical industry, specialising in custom-made mixers. Mervers also carries out construction work in port facilities, for example, the installation of large mixers. Mervers NV is based in Zwijndrecht (Belgium) and has a workforce of 25 employees.

The challenge

In 2011, an investment was made into a new 5-axle machining system. When the machine was first taken into use, it was found that for certain repetitive actions, a phenomenon occurred that was particularly irksome for the operator working on the new machine.

The problem came about primarily in situations where coolant was being used at high pressure, the consequences of this being that the coolant vapourised to an excessive degree. On opening the cabin, operators would come into direct contact with large quantities of vapourised coolant, causing irritation to the eyes and the respiratory tract. In seeking out help for the problem, Mervers contacted Plymovent, a company specialising in the installation of extraction systems in existing machines.

The solution

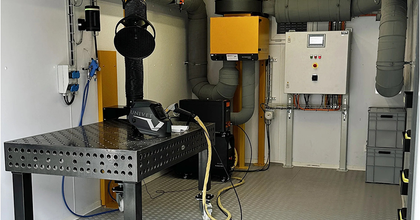

Given the nature of the mist and the machine’s volume, the suggested design included a duct connected to a type ME-42-F2 oil mist filter.

This unit has a maximum capacity of 2,000 m3 /h and that means that the air throughout the cabin is refreshed every 33 seconds. Care was also taken to keep the air supply in equilibrium with the air discharge via the chip-removal system. Filtered air is recirculated, that means throughout the rest of the workshop. This re-circulation has the advantage that any heated air in the workshop remains there.

The most important aspect was that the extraction unit caused no hindrance.

In addition to this practical consideration, another technical necessity came into play. In installing the extraction system, the intention was to get as close as possible to the source of the contamination. However, in this case, because of the movement of the spindle, it was impossible to install the unit in the cabin itself. For that reason, the extraction system at Mervers takes place via a duct through which the air is removed. The duct transfers the extracted air to the filter unit, which is positioned out of the way, against the CNC machine.

Main benefits

- The filter unit is stationary and, by definition modular, which means that it can be adapted in line with any expansion plans with respect to machinery and equipment.

- Low maintenance, a manometer specifies the status and indicates when the filter should be changed.

- Energy-saving due to re-circulation of air.

- The self-draining filter cassettes ensure effective filtration of oil mist.

- A working environment in which inside air quality is clean and there are fewer risks to health.

Testimonial

“This option was initially intended as a first step in solving the problem, as there was a suggestion that a second discharge pipe would have to be installed, although this wasn’t certain. I have to say, so far there’s been no indication this is necessary at all: the system is working perfectly so that operators are once again happy to work with the machine because there’s no longer any danger to health.”

Quote by: Mr. Van Hul, Production Manager at Mervers

Product list

Product

Application

- Metalworking processes using coolant at high pressure, 30 bar

Filter units

- Hydro filter

- Aluminium pre filter

- OC-1

- OC-2

- HEPA filter

"The operators of Mervers are once again happy to work with the machine because there’s no longer any danger to their health, as the Plymovent system works perfectly."

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all casesFiltration of welding/grinding fumes and oil mist

Multiple arms improve work environment

Case New Holland is the first to choose Plymovent’s latest product: the MDB-Compact!

Ventilation/filtration system main heat source

Effective welding fume extraction systems for all welding workplaces

Welders appreciate and value effectiveness of push-pull system

U-Push-Pull system defeats welding fume clouds

Complete extraction system ensures a safe working environment

Significant reduction of fume concentration

The risk of fire under control with shield fire safety solutions

Push-Pull system removes welding fumes effectively

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.