Safety of the welder ranks first

FIMA has been a resourceful partner in the manufacturing business of machineries for over 60 years. They have been developing and optimising their range of products and services constantly. Nowadays FIMA is a global player in the field of customised machinery manufacturing and is an effective partner for blowers, compressors, centrifugal dryers, bottom valves, engineering and support.

The company is distinguished by their outstanding innovative ability, their visionary capacity and solution-oriented activities.

The challenge

The existing workshop of FIMA has been equipped with a competitive welding fume extraction system for many years. In 2006 FIMA built a new production hall to extend their production capacity.

FIMA required a modern, user-friendly system which was regarded as most important demand for the 14 new welding workplaces. The extraction system of Plymovent was selected.

The extraction system of Plymovent fulfilled all requirements of FIMA, in many ways. The annual consumption of welding wire at FIMA is approximately 8-10 tons.

The solution

In order to capture the welding fumes in the production hall, the company management has decided to purchase extraction arms. The flexible extraction arms type UltraFlex-4 (length 4 m) and extension cranes NEC-2 (reach 2 m) with a total reach of 6 m were chosen.

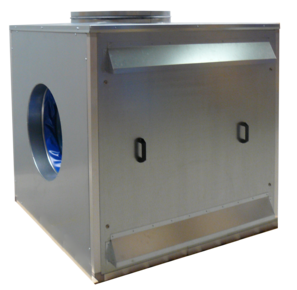

A central duct system connects the extraction arms to the central filter unit, type SCS, with pre separator and central fan type SIF-1500 (11 kW).

To minimise the heating costs the installation is equipped with a summer/winter switch (summer - exhaust to atmosphere, winter - recirculation of the air inside). To save space the filter installation is mounted on a platform.

(System installed with: Automatic start/stop + working light)

Main benefits

- The system turns on and off automatically

- Extraction arms are easy to operate

- A frequency inverter provides for the optimum extraction capacity, based on the number of extraction arms which are actually in operation

- Clean, safe and healthy work environment

Testimonial

“An innovative and powerful system where safety of the welder comes first, without unnecessary waste of energy. That’s why we choose Plymovent.

The best extraction system does not make the best weld. However, the best extraction system is available anyway!"

Quote by: Mr. Wengert of FIMA

Product list

Products

"An innovative and powerful system where safety of the welder comes first, without unnecessary waste of energy. That’s why we choose Plymovent."

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all casesWelders appreciate and value effectiveness of push-pull system

Case New Holland is the first to choose Plymovent’s latest product: the MDB-Compact!

Effective removal of welding fumes & dust

The right extraction for a high-pressure aluminium die-casting machine

U-Push-Pull system defeats welding fume clouds

MistEliminator units create a clean environment

Extraction arms contribute to the ISO 14001 & 26000 policy

Push-Pull system removes welding fumes effectively

Filtration of welding/grinding fumes and oil mist

Effective welding fume extraction systems for all welding workplaces

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.