Filtration of welding/grinding fumes and oil mist

Årjängs Verktygsindustri AB manufactures tools, machines, peripherals and aids for industry. Since Årjängs Verktygsindustri was established in 1981.

Our clients range from small businesses to major industrial groups and operate in a wide sector from the clothing industry to heavy processing industry and enterprises selling services.

The challenge

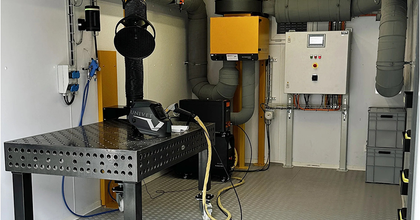

Welding and grinding for dry applications, oil mist captured via hoods for tempering furnaces as well as local extraction for processing machinery are part of the operations of Årjängs Verktygsindustri. They reached out to Plymovent because they needed an installation that improved the air quality at their workshop.

The solution

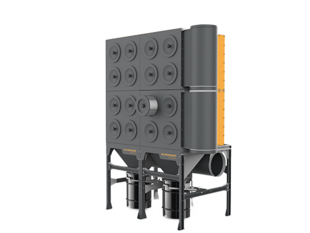

Welding and grinding fumes from dry application are captured directly at source via Plymovent’s local extraction, the KUA and the MultiSmart extraction arms. These fumes are then filtered in a self-cleaning filtration unit, Plymovent's MultiDust® Bank B-4.

Oil mist is captured via local extraction and via hoods for tempering furnaces and filtered using a five-step oil mist filter, Plymovent's MistEliminator ME-32.

Main benefits

- The filtered, heated air passes through a heat exchanger before being recirculated to the workshop room. All filters and units are frequently controlled for optimal functioning

- Efficient filtration of welding and grinding fumes

- Parallelogram arm ensures one touch smoothness and stays firmly in place

- External arm chassis provides strong support and outstanding stability, support and balance

- Comply with health and safety standards

- Minimise health risks in the workplace

Product list

Products

- 4 x MultiSmart Arm/KUA arms

- 1 x ME-32 oil mist filter (MistEliminator)

- 1 x MDB B-4 self-cleaning filtration unit

- 1 x CONT-C24 pressurised cleaning automation

- 5 x ASE-12 automatic dampers

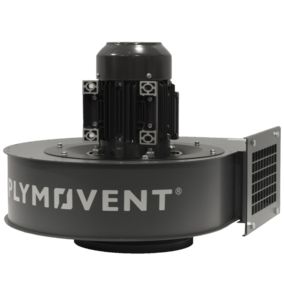

- 1 x FUA-4700 fan

- 1 x TEV-765 fan

- 2 x DCV frequency inverter

Application

- Welding and grinding for dry application

- Oil mist from processing machinery

Find more information about the products here!

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all casesExtraction arms contribute to the ISO 14001 & 26000 policy

Effective removal of welding fumes & dust

U-Push-Pull system defeats welding fume clouds

Complete extraction system ensures a safe working environment

Ventilation/filtration system main heat source

Effective welding fume extraction systems for all welding workplaces

Welders appreciate and value effectiveness of push-pull system

MistEliminator units create a clean environment

The right extraction for a high-pressure aluminium die-casting machine

The risk of fire under control with shield fire safety solutions

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.