Production lines with plenty of room in newbuild production hall

VDL VDS Technische Industrie in Hapert is specialised in stamping work (medium-sized and large runs). Pressing takes place fully automatically up to 800 tonnes. The primary activities are thin sheetwork such as cutting, stamping, spot welding, CNC spot welding, CNC diecutting and robot welding. Other work includes 3D laser cutting, seaming and assembly.

VDL VDS Technische Industrie works together closely with VDL Gereedschapmakerij. Both companies are part of the VDL group, an international industrial company which focuses on the development, production and sale of semimanufactured products, buses and other end products, and the assembly of passenger cars.

The challenge

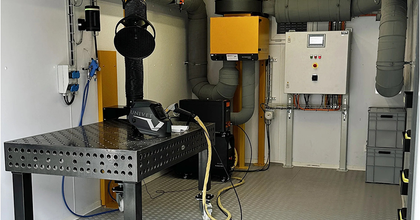

Various production lines had to be set up for a newbuild hall at VDL VDS for a range of welding work for the automotive industry. These production lines had to be fitted with welding workstations. The welding work makes use of spot welding machines, manual welding stations and welding robot units.

There was a specific challenge with regard to the welding robots. These weld a large number of stamped components for the automotive industry. The components are covered with a film of oil which is needed for the stamping process. This oil creates an additional fire hazard in the filtration system. We had to look for a solution which would minimise the fire hazard.

The solution

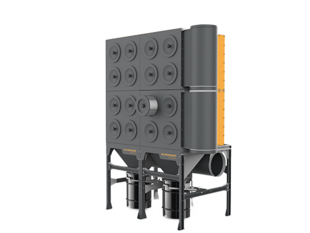

It was decided to work with two production lines and two separate manual welding stations. Wherever possible, we made use of source extraction using various Plymovent extraction arms. Source extraction is used for the spot welding machines and the manual welding stations. The welding robots are located in separate welding boxes and fitted with extraction hoods produced by VDL itself. These extraction hoods are connected to a filtration system supplied by Plymovent. This comprises two MDB-24s. This is a heavy filtration system which is very suitable for the filtration of large quantities of welding fumes.

Before the extracted welding fumes enter the filtration units, they first pass through two SparkShields. These are spark suppressors which was developed especially for Plymovent, with its own unique engineering. The SparkShield is a fire safety product, developed to minimise the fire hazard in the filter and increase the lifespan of the filter. A centrifugal acceleration ensures that sparks are removed from the constant airflow. A waist drum collects all remaining sparks at a safe distance from the main filter, and out of the way of the main pipe system. The waist drum can be easily removed and emptied, even during working hours.

As the welding robots primarily work on components which have undergone processing with oil, additional attention had to be paid by Plymovent to fire safety.

It was decided to work with two OilShields. An OilShield is a limestone dispenser which transports limestone continuously to the pipe system. Oily welding fumes form a serious fire hazard and can result in high costs for replacement of blocked filter cartridges. OilShield minimises the risk of fires in filter cartridges and spontaneous fires in the waist drum. Another advantage is that limestone is cheap. The high operational reliability is also unique. OilShield is fitted with two agitators which keep the limestone constantly moving in the funnel and in the dispensing unit. The design of the agitators was specifically geared towards the characteristics of limestone. This technology ensures a steady and uninterrupted supply of limestone.

Main benefits

- A clean, safe and healthy work environment.

- Complies with the requirements set out in Netherlands legislation.

- Wherever possible, clean and hot air is recirculated (resulting in lower heating and ventilation costs).

- Greatly reduced fire hazard through use of SparkShield and OilShield

Testimonial

“The primary focus in terms of setting up the new hall was that we wanted to create the safest possible work environment for our employees. The space also had to be structured as efficiently as possible. A third important point for us was the overview within the large space.”

“The production lines are set up in parallel to one another, which provides a good overview and ensures that all workstations provide easy access, to employees but also to cherrypickers, for example. By using a clear layout, we have automatically created greater safety and efficiency.”

Quote by: Hans Maas, Assistant Production Manager at VDL VDS

Product list

Products

"We have received many positive reactions from our visitors about the look of the new hall. People think that optimum use has been made of the space, and that it looks good visually."

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all case studiesMistEliminator removes oil mist effectively

Optimized filter system modification of the Audi RS5

Exhaust extraction for Mazda workshop in Paramatta Australia

Extraction of exhaust gases in vocational colleges

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.