The SCS-Diluter Pro voldoet aan de volgende richtlijnen:

- Machinerichtlijn 2006/42 EC

- EMC 2014/30 EU

- LVD 2014/35 EU

- ErP richtlijn 2009/125 EC

- Richtlijn 2011/65 EC (RoHS)

In some cases, source extraction and hoods are not an option, for example if metalwork pieces are too big to be covered by extraction arms, as in the ship-building and transport industry, or if welders constantly move in between positions. Plymovent has therefore developed a general filtration system that can control welding fumes in large facilities: the SCS-Diluter.

This solution can be used in large workshops with various welding processes, changing activities, crane transportation and locations where ductwork is difficult to install. The result: reducing the concentration of fumes to lower levels, giving a cleaner working environment!

Installing the Diluter system is easy as you do not need any ductwork. It does not only save ductwork costs, it is also a very flexible solution for facilities with many welding processes, changing locations constantly.

The Diluter system consists of three main components: the SCS-filter unit, a fan and the Diluter itself. The Diluter is an air circulation unit with six multidirectional outlet nozzles. The unit re-circulates the cleaned air into the workshop by means of the outlet nozzles.

The nozzles can be rotated to optimise air distribution. The airflows from the nozzles can be controlled individually making the system unique. Positioning the nozzles directly towards the welding fume layer gives the best result (usually between four and six meters (13 and 20 ft)). The main benefit is the relatively small investment for controlling welding fumes in your plant.

The SCS-Diluter will be available with the new filter controls of Plymovent; the ControlPro and the ControlGo.

The SCS-Diluter PRO is fitted with the ControlPro. This version has a control with an intuitive touchscreen interface that shows at a glance how the system is performing, what the system is doing now, will do next and how to keep it in shape. An extensive and very accessible menu allows full adaptability in an easy way. ControlPro uses ethernet communication for a wide variety of connectivity options. ControlPro is the control that meets the full needs of the professional user: Simple, Insight, Connected.

If your filters are steered by ControlPro control systems, Plymovent gives the option to extend it with ControlPro Connect. This is an advanced web portal that gives you the power to monitor, manage and control any number of filters at a glance from your PC, tablet or smartphone. This version uses the FCC-150 filter cartridge and has an operational airflow of (max.) 9000 m3/h (5,297 CFM)

The SCS-Diluter GO has integrated control unit the ControlGo. The ControlGo is built on the same platform as the ControlPro, offering the same performance, but with preset configurations for the user with basic needs. The SCS-Diluter GO uses push buttons and indicator lights for simple interaction and meets the basic needs of any user. This version uses the FCC-150 filter cartridge and has an operational airflow of (max.) 9000 m3/h (5,297 CFM)

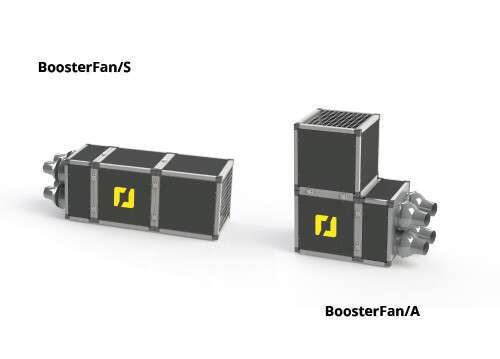

In situations where the Diluter filter capacity is sufficient but the workshop or the distance between diluters is too large, the booster fan is used to complete the air circulation. Plymovent offers the booster fan in two types with different functionalities.

These booster fans are also the solutions to prevent the air from getting stuck in a blind spot of the workshop, such as dead corners, niches and in case of L-shaped workshops.

Our experts will be pleased to help you find a solution for your unique situation! Click here to get in touch with them.

The SCS-Diluter Pro voldoet aan de volgende richtlijnen:

Hieronder vindt u enkele installaties van dit product bij onze klanten.

Vanwege de bouw van een nieuwe fabriekshal bij Holtkamp moet Plymovent een flexibele lasrookoplossing vinden die zich aanpast aan het veranderende proces.

Breman Machinery in Genemuiden heeft al bijna 150 jaar ervaring met het bewerken van metaal. Inmiddels beschikt het over een uniek machinepark en een groeiende kring opdrachtgevers.

Fortaco bestreed lasrookproblemen met afzuigarmen. Vanwege de grootte van de werkstukken konden lassers de afzuigarmen niet verplaatsen bij verandering van een laspositie.

Arginta Engineering besloot dat zij extra bescherming tegen las/snijrook en slijpstof nodig hadden. Ze contacteerden Plymovent om een oplossing te vinden.

CSM hecht veel waarde aan de werkomgeving van zijn werknemers en had een aantal rookafzuigers in gebruik. Dit was onvoldoende, waardoor CSM zocht naar een betere oplossing bij Plymovent.

Bekijk de volgende opties

Het MDB-Diluter-systeem is een vrijstaand ruimtelijk filtratiesysteem, dat is ontwikkeld om de achtergrondconcentratie van zware lasrook in een werkplaats te verminderen en onder controle te brengen.