No more complaints about welding fumes

Voortman Staalbouw is a modern company. Its specialised in the construction, production and assembly of steel constructions, roof and wall linings, stairs and landings. With approximately 120 employees, they carry out full projects as well as partial orders for clients, architects, building offices and their building contractors. Ensuring dimensional accuracy, efficiency, security and quality are of great importance.

The challenge

In 2003 Voortman Staalbouw moved to a new workshop of 140 m long x 22 m wide. During the design stage they took purchasing a welding fume filtration system into consideration. In view of the stringent environmental legislation and to meet the TLV values for welding fumes, Voortman strongly focused on proper and effective removal of welding fumes.

Pollution in the workshop is not only caused by welding fumes, but also by dust emission from cutting torches, grinding, drilling and sawing.

Voortman’s annual welding consumption is approx. 45 tons of massive wire. Fork-lift trucks also contribute to the level of pollution. Hot welding fumes rise to approx. 4-6 m high, where it forms a layer. This layer gets thicker during the day. At night, when the air gets colder, the layer of welding fumes come down. The roof fans that were installed in the old facility were not capable to remove all the welding fumes properly anymore.

The solution

Due to the large sizes of the work pieces (up to 30 metres) and very frequent changes of the welding activities, source extraction was not possible, which they already knew from the past. Because of this, a general filtration system appeared to be the best solution.

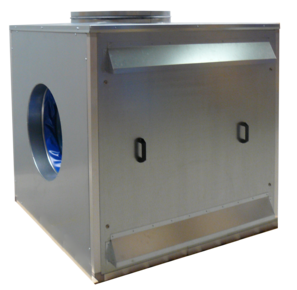

In this case, the workshop (140 x 22 m) was divided into four sections. Every section is equipped with a parallel shaped push pull system, consisting of two SCS filters and two SIF-1200 each. The filter units and fans have been integrated in the pillars at the long sides of the workshop.

The installation height of the system is 5 m. The rising welding fumes are captured by the horizontal flow of the push-pull system and blown to the inlet grids. After filtering, the air is blown back into the workshop by the push grids. A number of 6 air changes per hour guarantee a continuous removal of the welding fumes and other particulates. Large workpieces are moved in and out regularly through automatic doors, which ensures sufficient supplement of fresh air.

Main benefits

- The installation runs during all working hours. This guarantees a continuous filtration of the air, thus preventing accumulation of the welding fumes.

- Measurements of the air quality showed very satisfactory results.

- The welders may decide themselves to wear an overpressure helmet or a usual welding helmet.

- In 2005, the facility has been extended with a new hall and provided with the same type of general filtration system.

Testimonial

“This general filtration system ensures a good working climate. Not only for the welders, but for the other employees as well. A clean facility contributes to pleasant working conditions and a positive image of the entire company.”

Quote by: Harry Nijkamp, Quality Assurance Manager at Voortman Steel Group

Product list

"In the past welders always complained about the welding fumes. Now we’ve got the perfect solution."

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all casesMobile welding fume extractors ensure flexibility

A healthier working environment thanks to spatial welding fume extraction

Multiple arm system at Lasbedrijf Wero

General filtration systems ensure clean air at work

Flexible welding fume extraction system in plant

A “clean air in the shop” is one of their top priorities in the planning and design

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.