Multiple arm system at Lasbedrijf Wero

In the beginning of the 1980s, the main focus of Jos van der Lubbe, the parent company, was installing cables and pipes. In time, the company further expanded its activities with civil and hydraulic engineering and fiberglass technique. With the 2005 takeover of the welding company Lasbedrijf Wero, any necessary welding activities can be carried out in-house.

By now Jos van der Lubbe, with approx. 70 permanent employees (gas and water fitters, steel welders, steel fitters, groundworkers, cable installers, fiberglass blowers, section engineers, planners and administrative staff), has become a medium-sized market player.

The challenge

After moving into their new building in Nieuwendijk, the Netherlands in 2009, Lasbedrijf Wero started looking for an efficient welding fume extraction system.

The welding works take place both inside specifically designed welding cabins and outside these cabins in the public hall. Lasbedrijf Wero insisted on several, very acceptable, requirements for the new extraction system: it had to be low-maintenance, easy to operate and with a good quality-to-cost ratio.

The solution

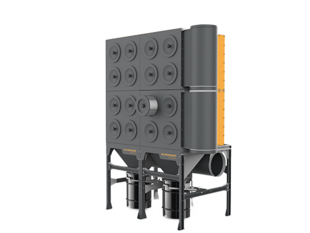

Due to the low ceiling in the welding cabins, the choice automatically fell on the extraction arm type UltraFlex-4/Low Ceiling. By mounting the extraction arms on the front of the welding cabin, optimal usage is made of the extraction arms, both inside the welding cabins and outside these cabins in the public hall. The UltraFlex-4/LC is a flexible extraction arm with a diameter of 203 mm. Specifically designed for spaces with a height of 3 meters or less. This extraction arm has a working range of maximum 3.75 meters. The ideal extraction arm for this location. Through routed ducting, the extraction arms are connected to a pressured air cleaned central filter, type MDB-4F, which has a capacity of 3,000 m³/h and a filter cloth of 60 m².

With this purchase Lasbedrijf Wero has invested in a clean and safe work environment for the welders.

On top of that, the installation meets the requirements as stipulated in the ‘practice guideline welding emissions’ 2010. An efficient extraction system has been made available for work activities both in and outside the welding cabins, The key word user-friendliness; automatic on/off switching of the extraction arms, constant extraction flow rate and self-regulating compressed air cleaning.

Main benefits

- User-friendly

- Energy efficient (fully-controlled)

- Meets the code of practice

- Very latest in technology

- Low noise

The extracted air is regulated through a summer/winter switch circuit. This switch circuit ensures that during wintertime warm filtered air is blown back into the hall, while in summer the air is directed outside via a roof feed-through, keeping the hall reasonably ‘cool’.

Type of installation

Products

• MDB-F4 + 4 arms; UltraFlex-4/Low Ceiling

Welding process used

• MIG/MAG

Material

• steel

Number of welders

• 4

Welding current

• 200 A

Engagement time

• < 15%

Concurrency

• 100%

Size of work pieces

• small/medium

Dimensions welding

• cabin: 5m x 5m x 3m

Type/amount complementary materials

• 3,500 kg/year

"If women wearing a skirt would be standing underneath the extraction arms, Marylin Monroe could learn a thing or two."

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all cases