A “clean air in the shop” is one of their top priorities in the planning and design

The Bucket Shop (TBS) is a Timmins, Ontario based heavy equipment repair, rebuild, and manufacturing facility that produces their own TBS HiPER brand line of cast lip and heel assemblies for mining equipment, as well as a unique 2, 4, and 6-piece bucket design. They stock full steel sheets in bulk, manufacture components in their own machine shop, and can roll or form their own plate requirements.

The challenge

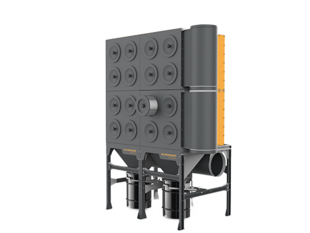

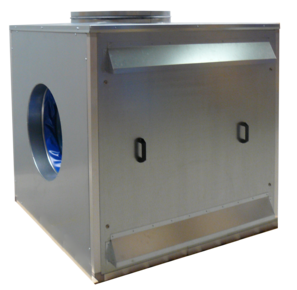

TBS moved into their a multi-million-dollar new facility in 2017, which includes an industry leading research and manufacturing area as well as state-of-the-art solutions in industrial clean air systems. At TBS, they combine both “Push-Pull & Source Capture Technology”. In most if not all industries, production output ranks the highest on any business owner’s priority chart. In the case of TBS, clean air and worker safety ranks just as highly. While planning and designing of their new facility, the air quality system had to be configured for 27 welding stations, a 100’ long plasma cutting table, and multiple sources for grinding and torch cutting.

The solution

After successfully being granted this project over many bidders, Plymovent got right to work with the task at hand. Right from the projects inception, our sales and engineering department were in constant communication with all of The Buckets Shops resources: the TBS principals, mechanical & structural engineers, architects, electrical, and general contractors, etc.

Plymovent supplied a complete “turn-key” package to the client which included engineering services, product supply, mechanical installation, and electrical hook up. System balancing, testing, and commissioning were conducted all upon completion to ensure all was as per plan.

Our project scope revolved around the main production areas.

The Heavy Bay, the Large Middle Bay, and the Small Middle Bay. Each one of these areas were addressed with a combination of technology principles. Both “Push Pull and Source Capture” ventilation concepts were used in the “Middle Bays” while the “Source Capture” concept is used exclusively in the Heavy Bay.

Main benefits

- A clean safe working environment right from day 1

- A clean building that will stay clean

- A new state of the art facility to be proud of which speaks volumes to their staff, their existing clients and their prospective clients alike

- Technology that supports the high profile required to operate as a respected global company

- A tool that supports attraction and retention of employees and adds value to prospective partners and clients

The beauty of using a push-pull system in conjunction with source capture system is that whatever is not being collected at the source due to the extractors range and accessibility, is readily captured and filtered by the Push Pull Systems and its laminar air currents. It’s the best of both worlds!

Testimonial

"Plymovent partnered with us to design a solution that met the needs of our industrial facility. They also supported a second dedicated system that was part of our new training environment. They will be top of mind for any future requirements. As such we endorse their performance, expertise, and value for any company needing professional support for the design and implementation of a system that creates a healthier workplace environment."

Quote by: Paul Woodward, Vice President of The Bucket Shop

Product list

Products

"We endorse Plymovent's performance, expertise, and value for any company needing professional support for the design and implementation of a system that creates a healthier workplace environment."

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all casesA healthier working environment thanks to spatial welding fume extraction

Extraction equipment meets strict demands

Mobile welding fume extractors ensure flexibility

General filtration systems ensure clean air at work

Multiple arm system at Lasbedrijf Wero

No more complaints about welding fumes

Push-Pull system: the ideal solution for large parts

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.