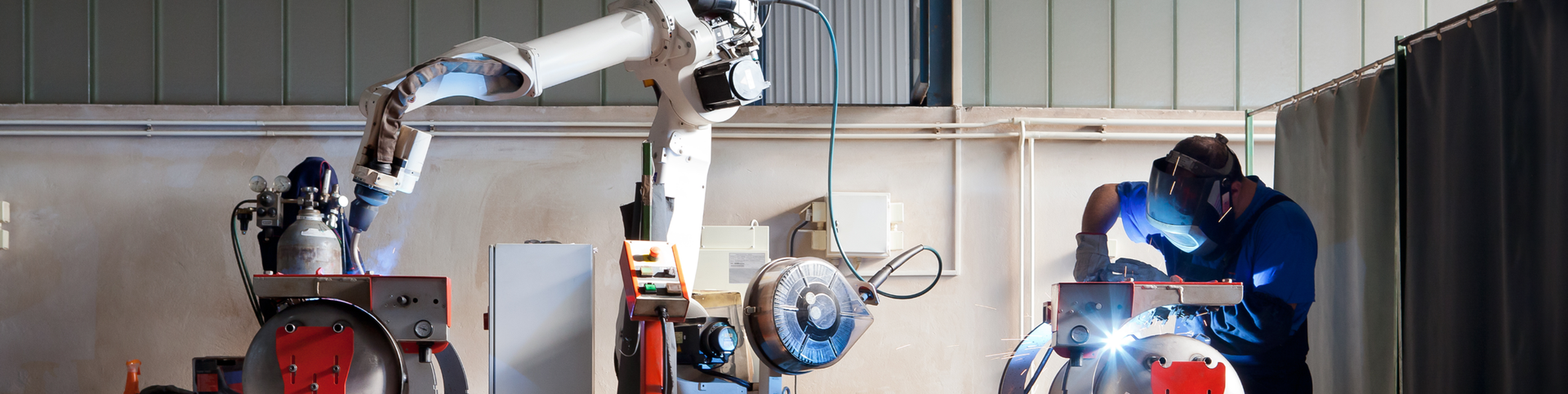

Many different working processes are taking place during the fabrication of tools and components. Processes such as milling, drilling, honing, casting, grinding, heat treatment and cold forming. Various oil and emulsions are used to cool or lubricate the metal components during these processes. An aerosol forms if these fluids get airborne. Slippery floors and work surfaces are caused by this oil mist. It often have negative health effects. In addition, these fine droplets can affect the electrical equipment in the facility.

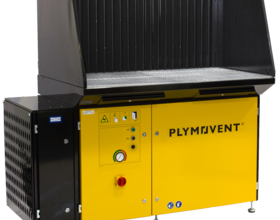

Plymovent offers various solutions to remove the oil mist. Our MistWizard needs to be attached to a single CNC-machine to give the operator a clear view of the production process. This eliminates the need for duct work and complicated electrical connections. Most preferably our FlexHood, connected to a MistWizard, is installed above an open CNC-machine to catch the airborne particles.

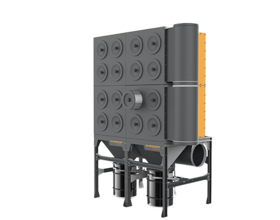

For larger solutions we can offer our MistEliminator, a modular filter bank that can be expanded as your business grows. This filter system removes the oil mist from the air, and depending on the metalworking fluids used, it can be re-used in the production process. The filtered air can be ventilated to the outside or recirculated into the factory, saving energy and reducing your heating costs.