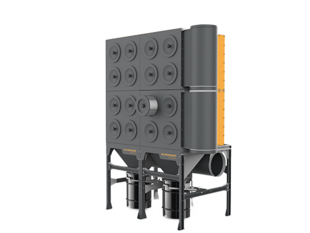

Ventilation/filtration system main heat source

K.S. Smede og Montage based in Taastrup, Denmark supplies all kinds of forging and assembly work. Blacksmith K.S. specialises in steel constructions, repairs, railings, spiral staircases, handrails, platforms, etc.

The challenge

K.S. Smede og Montage, a smith’s working-place, was about to expand their business and move to new premises. As they were expanding, K.S. Smede og Montage took this opportunity to purchase a new ventilation/filtration system to extract welding fumes and grinding dust more effective.

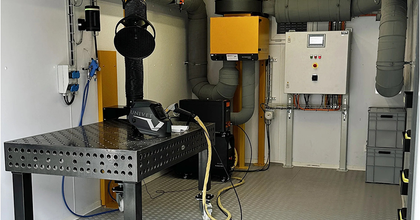

One of the main requirements was that the primary heat source in the workshop must become this new ventilation/filtration system. The second requirement was flexibility. Therefore, K.S. Smede og Montage choose the most effective solution: at source extraction. Seven extraction arms were spread throughout the workshop connected to a ductwork system. K.S. Smede og Montage insisted on several other - very acceptable - requirements; the extraction arms needed to be easy to operate and should have a good quality-to-cost ratio. K.S. Smede og Montage installed the system their selves with instructions of the supplier.

The solution

The choice was crystal clear: a MultiDust® Bank filtration system, combined with extraction arms, type FlexMax. The system contains: 7 KUA extraction arms, extended with FlexMax extension cranes. FlexMax is the perfect extractor for welding high objects. For example, objects (at height) either close to or far from the mounting point of the arm. This extraction arm can be positioned in one simple movement, anywhere within a radius of approx. 9 m width up to 8 m high.

The cleaned indoor air is being redirected into the workshop, functioning as a primary heat source. Often, valuable, extracted air is channeled outside. Heat recovery was the ultimate goal of K.S. Smede og.

The extraction system is controlled on demand via three frequency converters and a joint PLC board, saving energy.

Dansk Procesventilation gave advice and finally designed the extraction system. The distributor prepared the necessary drawings for the installation.

Main benefits

- Heat recovery (primary heat source)

- Efficient filtration of grinding dust and welding fumes

- Differential pressure-controlled filter cleaning

- Flexible positioning of inlet and outlet

- Modular design, makes expending in the future easy

- Filter unit placed on the roof, saving expensive floor space

- Low cost of ownership

Product list

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all casesThe risk of fire under control with shield fire safety solutions

Welders appreciate and value effectiveness of push-pull system

Filtration of welding/grinding fumes and oil mist

The right extraction for a high-pressure aluminium die-casting machine

Case New Holland is the first to choose Plymovent’s latest product: the MDB-Compact!

Complete extraction system ensures a safe working environment

MistEliminator units create a clean environment

Multiple arms improve work environment

Push-Pull system removes welding fumes effectively

U-Push-Pull system defeats welding fume clouds

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.