Case studies

Flexible welding fume extraction system in plant

The welding and turning activities take place in two separate production halls. Most work is based on projects, this means that flexibility is extremely important.

Welders appreciate and value effectiveness of Push-Pull system

Welding fumes are extremely fine and volatile and contain suspended metal particulates. We wanted to protect our operators from those particles.

Extraction arms contribute to the ISO 14001 & 26000 policy

Welding fumes accumulated into the workshop and generated a ‘blue layer’ inside the building. In order to remove this vast amount of welding fumes Mimault needed a professional extraction and filtration system.

FlexHood fulfills Edmolift’s demands

Edmolift UK Ltd challenged Plymovent to supply an extraction system that prevents welding fumes and welding dust covering stock in the warehouse.

The right extraction for a high-pressure aluminium die-casting machine

Pedeo’s newest high-pressure aluminium die-casting cell must be fitted with an extraction system to safely remove the fumes and vapours that are released.

Extraction arms remove dust effectively

Micron was looking for an effective dust control device with filters to ensure easy maintenance. Plymovent was challenged to get the dust levels under control.

Plymovent sponsors The Welding Academy

The Welding Academy at Peterlee (United Kingdom) has a 10,000 sq. ft. workshop. In this workshop twenty students can use the MIG, TIG and MMA welding equipment.

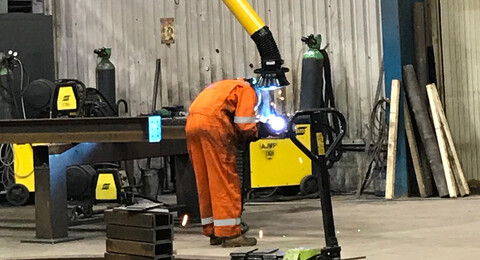

AJ Engineering

In 2017, AJ Engineering secured its biggest contract to date with a multi-million-pound windfarm deal, this was to fabricate and install the structural steel and cladding.

NY fire dept. adds vehicle exhaust removal system for firefighter & EMT health

The previous system had design flaws, and would not release, causing the product to be damaged and unusable. It was causing more damage than good to both the firefighters and the station.

Magnetic grabber ensures effective exhaust removal

The Magnetic Grabber® was installed to an existing SBT Pneumatic system in order to avoid unnecessary additional costs.

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.