Case studies

Complete extraction system ensures a safe working environment

Isolating the welding process improved workspace cleanliness and product quality. With increasing demand for welding services, RuossTech collaborated with Absaugtechnik Wild AG to install an advanced ventilation system that ensured optimal container performance.

Case New Holland is the first to choose Plymovent’s latest product: the MDB-Compact!

In one of the many production workshops in Zedelgem, there was a need for a new welding fume extraction system. It goes without saying that CNH contacted Plymovent.

Effective removal of welding fumes & dust

The welding activities at Scania generate a lot of welding fumes. Plymovent installed a multiple arm system, extraction hoods, central filter system.

Safety of the welder ranks first

FIMA required a modern, user-friendly system which was regarded as the most important demand for their 14 new welding workplaces. The extraction system of Plymovent was selected.

Air quality in the welding shop

At the beginning, the welding fumes of the production facility were extracted by two fans. Soon this kind of extraction was not sufficient enough anymore, resulting in considerable fume and dust nuisance.

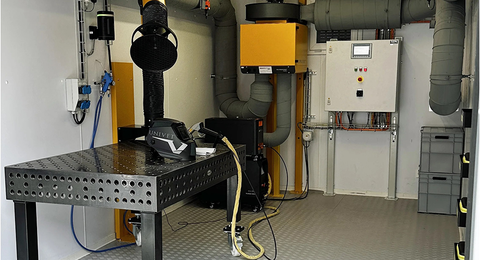

Effective extraction systems in testing area

The welding fumes of the two welding robots are captured by extraction hoods and filtered by two self-cleaning cartridge filters type SFS.

Clean air in the welding shop

An existing hall has been rebuilt into a new welding shop because of the strong growth of KettenWulf. Upon completion the hall should be finished with a well-designed extraction system.

A “clean air in the shop” is one of their top priorities in the planning and design

While planning and designing of their new facility, the air quality system had to be configured for 27 welding stations, a 100’ long plasma cutting table, and multiple sources for grinding and torch cutting.

Multiple arm system at Lasbedrijf Wero

After moving into their new building in Nieuwendijk, the Netherlands in 2009, Lasbedrijf Wero started looking for an efficient welding fume extraction system.

Hessels is also going for the experience and expertise of Plymovent!

The challenge at Hessels Zeefbanden was to not just provide the customer with an extraction solution for the metalworking process, but also a suitable one for their post process.

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.