Clean working environment without oil vapours

Voortman Staalbouw, with over 40 years in the business, is one of the Netherlands largest steel contractors. The company has been run by the second generation of the Voortman family since 2001. Voortman is part of the Voortman Steel Group. The Voortman Steel Group consists of eight innovative, internationally operating companies.

The challenge

Voortman Staalbouw is a modern company located in Rijssen – a city in the Twente region of the Netherlands renowned for its construction industry – with extensive experience in building steel structures for the industrial, infrastructure, system and commercial building sectors as well as for export. From its very strong position as a steel builder, Voortman has grown over the years to become one of the Netherlands largest steel contractors. Voortman’s ISO-certified construction process rests firmly on four pillars: BIMengineering, safety, innovations and durability.

Voortman is primarily active in the development and production of CNC-controlled steel processing systems, delivery and installation of different kinds of steel constructions, conservation and preservation of metals, delivery and installation of roof and wall cladding and construction of turn-key commercial buildings. Oil vapours are therefore a daily concern on the workfloor.

The solution

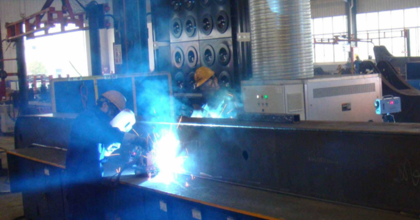

A wide range of metalworking processes are performed at Voortman. These include oxy-fuel cutting and plasma cutting. Both of these cutting processes produce lots of fumes.

The oil vapours must be extracted. In some cases regular ventilation is adequate, but the quantity produced at Voortman necessitates professional capture and discharge.

Voortman has worked closely with Plymovent for a long time, and various Plymovent products and systems have been installed over the years. For example, Voortman has a number of different Plymovent extraction systems to capture welding fumes.

For capturing and eliminating oil vapours Plymovent recommended MistEliminator units. These units are specially designed for oil vapours from CNC machines. The units can even capture and filter the oil, after which the customer can use it again (recycling).

A solution was also sought for the drilling processes. The drilling equipment uses a lubricant to cool the metal plates. Here, too, Plymovent recommended the MistEliminator unit.

Main benefits

- Effective extraction system; the operator of the enclosed CNC machine once again has a good view of the process.

- Clean, safer working environment thanks to the reduced presence of oil vapours.

- The lubricants can be reused.

- Higher productivity due to reduced sick leave (health complaints).

- Good work climate and high morale by providing a professional workshop; emphasis on the importance of the employee.

Testimonial

‘As a progressive technical company, we do our part to contribute to our living environment and society. Our employees enjoy a challenging working environment in which they have plenty of opportunities to develop themselves further. Our family company places great value on respectful relationships and personal entrepreneurship.’

‘A perfect working environment is essential to achieving these goals. That means a working environment that is both clean and safe. The Plymovent extraction equipment definitely contributes to that. All the welding fumes and oil vapours are effectively extracted, keeping the indoor air clean.’

Quote by: Mr. Voortman, Director Voortman Staalbouw

Product list

Products

- 2 x MistEliminator-32 3000 m3 /h incl. HEPA filter

- 2 x MistEliminator-F2 (435) fan in box 2,2 kW

- 2 x Motor protection switch MPS 4.0-6.3A

Applications

- Drilling

- Cutting

- Marking

- Punching

- Blasting

- Shearing

- Sawing

Find more information about the MistEliminator here!

"Our employees are important! They deserve a clean working environment."

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all case studiesPush-Pull systems in the transport industry

Optimal employee protection against welding fume

Fully controlled multiple arm system removes welding fumes effectively

Effective extraction systems in testing area

Minimum environmental impact, maximum air purity

Saving valuable energy during the heating season

MistEliminator removes oil mist effectively

Global preferred supplier with eds solutions

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.