Optimal employee protection against welding fume

Hamm Ag is the specialist to turn to for compaction technology on every continent, and they rank among the leading manufacturers of compaction equipment worldwide. The company’s head office is located in Tirschenreuth, Germany and owns the most modern roller plant in Europe. Hamm Ag is a member of the Wirtgen Group that operates internationally. More than 5000 people are working for the Wirtgen Group worldwide.

The challenge

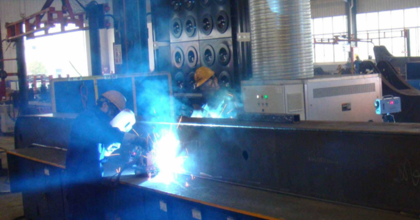

In the plant of Tirschenreuth the welding takes place in large, undefined working areas. They tried to improve the air quality through roof ventilation, but this led to a high energy loss. The hall is divided into two working areas. Each part is 38 meters long x 20 meters width x 6 meters high. The extraction volume of each part is 4500 m³. The airflow capacity of the new Plymovent system is currently 54.000m³/h. However, the maximum capacity of this system is 60.000m³/h.

The solution

We have installed a Push-Pull system with heat recovery and fresh air supply. This system extracts the rising welding fume from the work environment. As a result, the welding fume concentration is well below the MAC-value. To guarantee an optimal longitudinal airflow, 2 U-systems with a maximum capacity of 30.000 m³/h each, had been applied.

To keep the used floor space in the production hall as low as possible, the extraction systems are placed on the outside of the hall under a canopy.

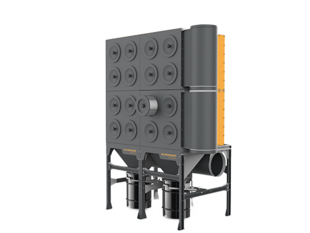

The welding fumes can be captured optimally with the installation of two extraction systems with a combined air flow capacity of 60.000 m³/h. Additionally two fresh air supplier-systems with a heat recovery system and post-heating units are offered to guarantee fresh air exchange even with closed doors and windows during the Winter. The real air intake volume is 12.000 m³/h, this means the indoor air in the plant is refreshed every hour. The air flow is controlled based on the demand, in other words, a frequency convertor controls continuously the rotational speed of the exhaust fans.

Our filter systems are certified for W-2 and W-3 according to the directives of the German Institute for Occupational Health and Safety. The offered extraction is declared as one according to welding fume category W-2. Here they handle exclusively with steel, so the circulatory air operation may run to 100%.

Main benefits

- Problem of small floor space is solved!

- Not only compliance with all legislation even a shortfall of legal limits!

Testimonial

“Plymovent GmbH solved two problems in our roller drum production facility. This was on one hand the high air pollution with welding fume particles and on the other hand the limited floor space. Based on the FumeSimulator of Plymovent the MAC-value (Maximum Allowable Concentration) has been calculated. In the end we did not only comply but reduced the concentration even below the 1 mg/m³.

In order not to lose any valuable floor space, we have placed the filter outside. I was especially impressed that all work took place without any significant disruptions to our operations and that the installation went smooth. The decision in favour of Plymovent was easy, facing these facts and the tailor-made solution offered. Even afterwards we still think the same”

Quote by: Mr. Dietmar Heinl, Safety Manager of Dep. Health & Safety at Hamm

Product list

Type of installation

- 2 x Push-Pull system MDB-30 + 37 kW Fan

- 4 x U-System 15.000 m³/h

Products

"Our employees are now optimally protected against welding fume. A good feeling!"

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all case studies