Case studies

Extraction arms remove dust effectively

Micron was looking for an effective dust control device with filters to ensure easy maintenance. Plymovent was challenged to get the dust levels under control.

Plymovent sponsors The Welding Academy

The Welding Academy at Peterlee (United Kingdom) has a 10,000 sq. ft. workshop. In this workshop twenty students can use the MIG, TIG and MMA welding equipment.

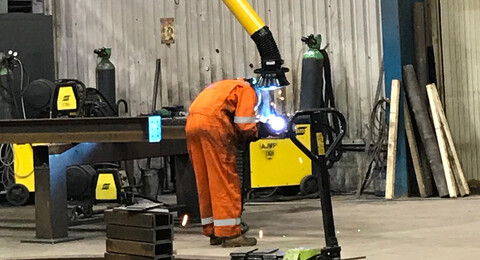

AJ Engineering

In 2017, AJ Engineering secured its biggest contract to date with a multi-million-pound windfarm deal, this was to fabricate and install the structural steel and cladding.

Push-Pull system: the ideal solution for large parts

Delmet was already acquainted with welding fume extraction, but its use of mobile units equipped with an extraction arm was far from ideal.

Clean air in all welding cabins

Welding work plays an important role in the work process. A total of nine welding cabins have been installed in a new part of the works.

Multiple arms improve work environment

The service workshop needed a high-quality extraction system to remove welding fumes, grinding dust and oil mist, preventing accumulation in the workshop.

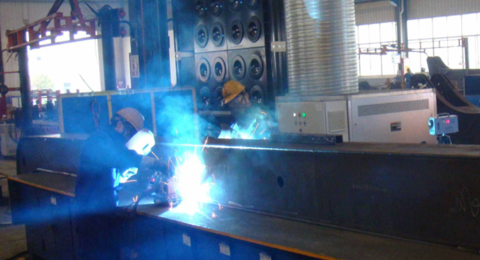

Push-pull systems in the transport industry

Zoomlion, based in China, produces all kinds of enormous vehicles/machines, e.g. to asphalt, pave, drill, sweep and wash, but also crane transportation, bulldozers and fire trucks.

Ventilation/filtration system main heat source

K.S. Smede og Montage, a smith’s working-place, was about to expand their business and move to new premises. They took this opportunity to purchase a new ventilation/filtration system.

Push-Pull system removes welding fumes effectively

ABB Estonia was in the middle of a restructuring programme when the production lines were reviewed. As a result, one new welding working area was created.

Global preferred supplier with eds solutions

Fortaco was managing welding fume problems with extraction arms. Because of the size of working pieces, welders could not relocate extraction arms when changing a welding position.

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.