Stork chooses central oil mist filer system

Stork Turbo Blading has been supplying to its partners from the power generating industry for more than 80 years. Stork Turbo Blading has two large production facilities for turbine parts, one in the Netherlands and one in the United States. The company is a specialist for the production of turbine blades and components for industrial steam and gas turbines. Stork Turbo Blading forms part of the Stork Group with a total of 14,000 employees working in the power, oil & gas and chemicals industry.

The challenge

The Stork production facility in Sneek has 17 machine tools that employ metalworking fluids. Part of these fluids are released as mist or fumes during the machining process.

In order to protect the health of the workforce, create a safe working environment and extend the service life of the machines and equipment, it is important to remove this oil mist and fumes.

Every machine tool installed at Stork was equipped originally with an individual filter system installed on top of the machine. The installation of a separate system on each machine tool made it difficult to ensure the continuity of the air flow, and filter maintenance was very time-consuming.

The solution

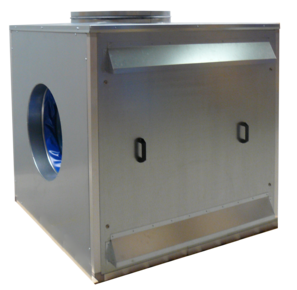

In order to optimise the extraction capacity, two MistEliminator banks were installed that are connected to eight and nine machine tools, respectively. By extracting sufficient air from closed, semi-open or open (CNC) machine tools, the oil mist cannot escape from the machine tool. This drastically reduces the background concentration of oil mist at the workplace. The MistEliminator is a modular filter system. The flexibility of the system allows it to be expanded or adapted to meet changes in the processes of the machine park.

The fully automated and centralised system ensures a constant air flow from the machines, and filter maintenance can be carried standing at one central point. The installation of an automatic valve at each extraction point on the machine that opens as soon as machining starts, the frequency controller can set the fan to precisely the required speed, thus saving energy.

Each filter installation consists of four units, each with an automatic valve on the upper side. The units are ‘switched off’ in turn at periodic intervals to give the filters time to drain into the collecting tray. The collected fluid is automatically pumped into a buffer tank.

Main benefits

- Meets legal requirements.

- Positive effect on the workplace climate because the oil mist is extracted from the air. The climate control system can thus function optimally without being impacted by contaminated workshop air.

- The extraction volume at each machine is controlled fully automatically from one central point.

- Maintenance can be done without an elevator platform or stairs.

Testimonial

"A safe working environment is a high priority at Stork. With this system from Plymovent, we can satisfy all the applicable health and safety standards and minimise the health risks on the shop floor."

Quote by: Bouke Stiensma, Head of Maintenance & Facilities Department of Stork

Product list

"Less is more is certainly true of this installation!"

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all case studiesFlexible welding fume extraction system in plant

Mobile welding fume extractors ensure flexibility

No more complaints about welding fumes

Extraction equipment meets strict demands

A “clean air in the shop” is one of their top priorities in the planning and design

Push-Pull system: the ideal solution for large parts

General filtration systems ensure clean air at work

A healthier working environment thanks to spatial welding fume extraction

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.