Extraction hoods keep working environment clean

The Hörmann Group –Europe’s leading supplier of doors and garage doors– has produced more than 15 million doors for global distribution since the company was founded in 1935. In 26 specialised factories in Europe, North America and Asia more than 6,000 employees develop and produce high quality garage doors, man doors, frames and drive systems for use in private and commercial buildings.

The challenge

Hörmann develops and produces doors of every imaginable type, including doors for the industrial market, such as dock seals for loading and unloading lorries, as well as garage and interior doors for the consumer market.

In their Alkmaar (Netherlands) factory Hörmann manufactures products such as dock levellers, dock shelters, dock and high-speed doors, and dock seals. In 2007, Hörmann expanded two production halls by an additional 2,000 m2. Today around 100 employees work at this location.

The expansion included the purchase of new welding robots to optimise the production processes in Alkmaar. Plymovent was then contacted for welding fume extraction systems.

The solution

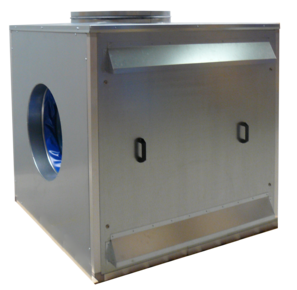

The Plymovent FlexHood extraction hood is specially designed for welding robots. An extraction hood with welding strips is an ideal product for isolating a welding machine from the rest of the work floor. This enables you to protect the people nearby and ensure that all the welding fumes remain within the extraction hood.

The choice for welding hoods was an easy one.

The SCS system was chosen as filtration system, because the welding fumes at Hörmann contain no oils. Ductwork connects the four extraction hoods to the SCS filter system. Because the system is equipped with frequency-controlled dampers it is also extra energy-efficient.

The contaminated air is filtered in the SCS system and then recirculated, which means the air is cleaned and then blown back into the workspace. This prevents valuable energy from being wasted.

The extraction hoods are suspended from the existing steel construction. This also makes optimum use of the workspace, without the need to install optional stands on the floor.

Main benefits

- Clean working environment thanks to effective welding fume extraction.

- Safe working environment; the welding strips keep sparks and spatter within the protected workspace.

- Cost-efficient solution; contaminated air is filtered and recirculated in the same workspace.

- Protection; the welding strips prevent personnel from looking directly into the welding light.

- Energy-efficient; thanks to frequency-controlled system.

- This system solution is frequency-controlled, based on a signal from a pressure sensor. The dampers open as soon as the welding robots start. The pressure sensor measures the pressure differential in the ductwork and signals the frequency controller. The correct flow rate is therefore maintained, regardless of which or how many extraction hoods are in use.

Testimonial

“We are extremely satisfied with the Plymovent extraction hoods. They were built to our exact dimensions. This means that only welding fumes are extracted, precisely where needed, in a screened-off area directly above the welding robot. The welding fumes are drawn off well, keeping the working environment clean and therefore safe.”

“We also opted for recirculation. This means that the welding fumes are first filtered. Then the clean (pre-warmed) air is blown back into the work area. This considerably reduces the ventilation and electricity costs.”

Quote by: Alexander Oud, Hörmann Alkmaar B.V.

"The extraction hoods contribute to a clean and safe working environment."

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all case studiesPush-Pull system: the ideal solution for large parts

General filtration systems ensure clean air at work

Mobile welding fume extractors ensure flexibility

A healthier working environment thanks to spatial welding fume extraction

Multiple arm system at Lasbedrijf Wero

A “clean air in the shop” is one of their top priorities in the planning and design

No more complaints about welding fumes

Extraction equipment meets strict demands

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.