The MDB-Diluter is in accordance with the following directive:

- CE

- UL: On fan motor and frequency drive

- RoHS: Directive 2011/65/EC

The MDB-Diluter system is a free-standing general filtration system, developed to reduce and control the background concentration of heavy welding fumes in a workshop.

MDB-Diluter systems are designed for intensive welding activities with heavy dust load. The unit prevents accumulation of welding fume beyond the legal limits by continuous filtration and dilution of polluted air. The blue haze of welding fumes, caused by the risen fumes that concentrate between four and six meters (13 and 20 ft) above the floor, is continuously mixed with clean air injected by nozzles.

Filtering and diluting the indoor air provides a healthier environment for all your employees, not only the welders who wear their welding ventilation helmets. Also for maintenance technicians, assemblers, machine operators and team leaders. The MDB-Diluter filters the blue haze instantly making it disappear into the filter medium. Another advantage of a cleaner indoor air is less dust deposits on your machinery and thus less downtime and lower maintenance costs.

The MDB-Diluter injects the filtered clean air into workshop. The airflow is completely adaptable in volume and direction to your situation with a throw of up to 50 meters (164 ft). The nozzles are individually adjustable and will not create a draft.

According to the international standards source extraction is always preferred, but for some workshops source extraction is just not (fully) possible. The MDB-Diluter is the ideal solution when source extraction and welding hoods are not possible.

MDB-Diluter can be applied if:

The MDB-Diluter PRO has BiCo spunbond polyester cartridges with PTFE membrane. The MDB-Diluter PRO is welding fume class W3 compliant. This membrane ensures that the dust particles are captured on the surface of the filter, acting as an instant dust cake. As a result, the filter can act at its peak performance right from the start, whereas filters without this PTFE membrane need to collect some dust first before acting at peak performance.

The MDB-Diluter is self-cleaning. This automatic filter cleaning takes place by compressed air pulses inside each filter cartridge. The RamAirTM pulse amplifier provides superior cleaning for longer filter cartridge life and lower pressure loss. The residue is collected in a 80 liters (21 gallons) dustbin on wheels and can be removed while unit is operational.

The silencer reduces the noise level of the air flow. The sound absorbing case reduces the noise of the fan motor running at maximum power to less than 70 dB(A).

The MDB-Diluter will be available with the newest filter control of Plymovent; the ControlPro. This control has an intuitive touchscreen interface that shows at a glance how the system is performing. The 7’’ touch display shows what the system is doing now, what it will do next and how to keep it in shape. An extensive and very accessible menu allows full adaptability in an easy way. ControlPro can use ethernet communication for a wide variety of connectivity options. ControlPro is the control that meets the full needs of the professional user: Simple, Insight, Connected.

If your filters are steered by ControlPro control systems, Plymovent gives the option to extend it with ControlPro Connect. This is an advanced web portal that gives you the power to monitor, manage and control any number of filters at a glance from your PC, tablet or smartphone.

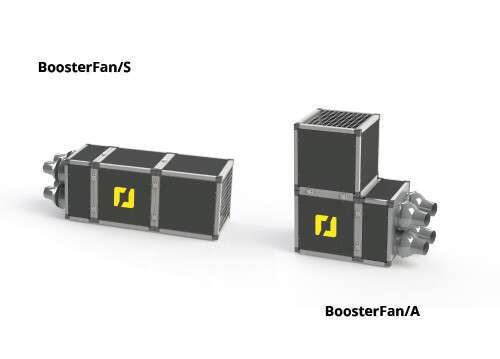

In situations where the Diluter filter capacity is sufficient but the workshop or the distance between diluters is too large, the booster fan is used to complete the air circulation. Plymovent offers the booster fan in two types with different functionalities.

These booster fans are also the solutions to prevent the air from getting stuck in a blind spot of the workshop, such as dead corners, niches and in case of L-shaped workshops.

Our experts will be pleased to help you find a solution for your unique situation! Click here to get in touch with them.

W3 compliant

(EN-ISO 21904-1:2020)

The MDB-Diluter is in accordance with the following directive:

Take a look at these options!

The SCS-Diluter is a stand-alone general filtration system, developed to reduce and control the background concentration of welding fumes in a workshop.

Contact our specialists now and get answers on all your questions regarding clean air.