Push-Pull system removes welding fumes effectively

ABB is a global leader in power and automation technologies. Based in Zurich, Switzerland, the company employs 145,000 people and operates in approximately 100 countries. ABB –in its current form– was created in 1988, but its history spans over 120 years. Today, ABB stands as the largest supplier of industrial motors and drives, the largest provider of generators to the wind industry, and the largest supplier of power grids worldwide.

The challenge

ABB is well-known as a supplier of motors and generators and operates worldwide. ABB has many offices and production facilities that ensure the smooth operation of the high-quality products and systems.

This case study is about the production facility in Jüri, Estonia.

ABB Estonia was in the middle of a restructuring programme when the production lines were reviewed. As a result, one new welding working area was created. ABB contacted the authorised distributor of Plymovent in Estonia, MECRO, to find a suitable solution for the removal of welding fume.

All aspects were looked at on site, to ensure an optimal solution for this specific working area.

The solution

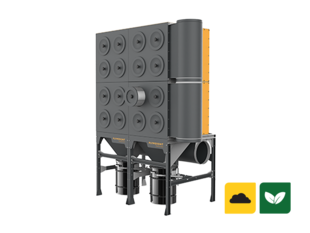

As ABB in Estonia was looking for a flexible welding fume extraction system, Plymovent opted for the Push-Pull system. This general ventilation and filtration system controls the concentration level of welding fume and ensures that the legal limits are not exceeded.

The working area where the Push-Pull system needed to be installed is 8 x 16 m. This working area is located in a production facility (hall) of 25 x 50 m.

Plymovent analyzed the situation and concluded the following:

- As the employees of ABB work with large metal workpieces, source extraction was no option.

- As the welding area is big (128 m2), an extraction hood is also no option.

The Push-Pull system is perfect for working areas like this. To make optimal use of the floor space, the filtration unit, fan and system control panel were placed on a construction platform. ABB went along with our recommendations to install the Constant Flow variant. A pressure transmitter installed in the ductwork is used to set the system volume at time of commissioning of the system. Logically, less power is required at time the filters are new. Depending on the operating hours, the pressure drop of the system will slowly increase during the lifetime of the filters. This pressure increase will be sensed by the pressure transmitter, which on his turn will command the frequency controller, to adapt the rpm of the fan motor.

With this system a Constant Flow is achieved against the lowest possible energy use.

Main benefits

- ABB meets the national Occupational Health and Safety Regulations.

- ABB ensures a clean, safe and healthy working environment for its employees.

- Welding fumes are extracted effectively ensuring that the concentration level of welding fume stays within the legal limits.

Testimonial

“While selecting a welding fume extraction system, we took different types of systems into consideration. Like extraction at the source, extraction in combination with heat exchanger and many more. In the end, we choose the Push-Pull system. Other systems interfered too much with our crane work, which is very important to us.

It was a bit tricky to adjust the air volumes in the right way, but the MECRO team managed to adjust the air volumes in a satisfactory way of which we still benefit. Now, we are actually thinking about reviewing the production, so we can use more Push-Pull systems in other welding areas too.”

Quote by: Toomas Valdt, Development Engineer at ABB Estonia

Product list

Products

"Now, we are actually thinking about reviewing the production, so we can use more Push-Pull systems in other welding areas too."

Need help?

WE'RE HERE FOR YOU

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all casesMultiple arms improve work environment

The right extraction for a high-pressure aluminium die-casting machine

Welders appreciate and value effectiveness of push-pull system

Filtration of welding/grinding fumes and oil mist

Effective removal of welding fumes & dust

MistEliminator units create a clean environment

Significant reduction of fume concentration

Hessels is also going for the experience and expertise of Plymovent!

Effective welding fume extraction systems for all welding workplaces

The risk of fire under control with shield fire safety solutions

U-Push-Pull system defeats welding fume clouds

We're happy to help!

Contact our specialists now and get answers on all your questions regarding clean air.